ERP Knowledge Base

How to conduct inventory forecasting - Inventory behavior pattern analysis?

Inventory issues - Traditional solutions in the past

- Urgent purchase orders

- Seeking additional suppliers

- To expedite deliveries, initiate early procurement, early deliveries, and early materials preparation

- Frequent material relocations

- Monthly inventory checks

- Stocking more inventory

Inventory issues

| Internal factors | External factors |

|---|---|

| Inaccurate scheduling | Frequent design changes |

| Discrepancies in material accounts | Customer order changes |

| Production defects | Customer rush orders |

| Material relocation issues | Inaccurate supplier delivery timelines |

| Low production efficiency | Incoming material defects |

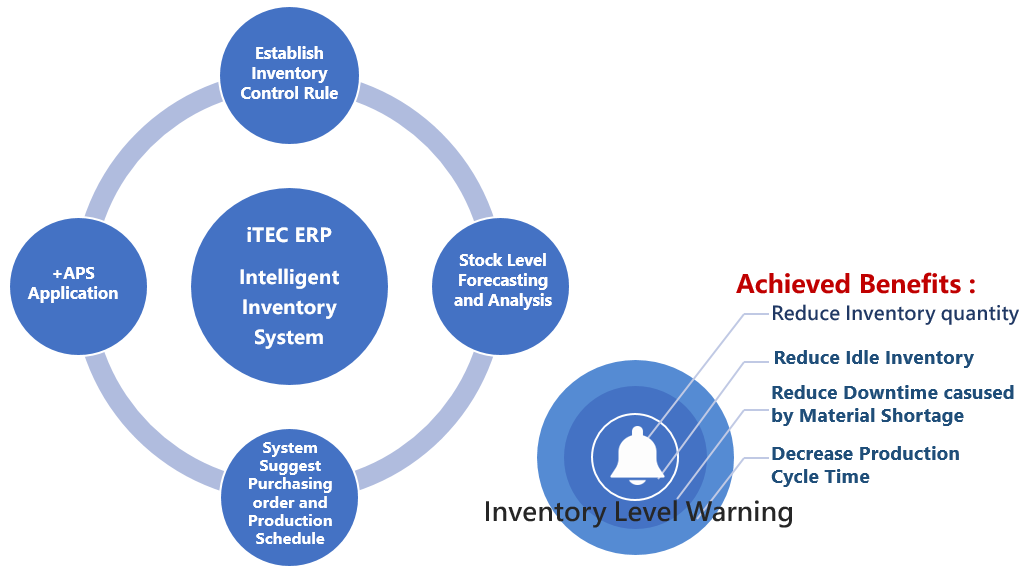

Intelligent level utilization - Supply-demand balance

| Item | Questions | Causing issues |

| Audit point 1 | Production is stable, but if inventory falls below the minimum safety stock level, it indicates decreasing demand. | Shortage |

| Audit point 2 | As demand varies over time, daily demand must be adjusted over time to maintain inventory levels. Failure to do so can lead to both excessive and insufficient inventory due to falling below the safety stock level. This indicates that demand should be adjusted dynamically based on data. | Fluctuations in inventory levels are caused by changing market demands and time. |

| Audit point 3 | With stable production, if inventory exceeds the maximum safety stock level, it indicates that inventory levels should be adjusted appropriately to avoid excess or shortage issues in the future, which can lead to stockouts or excess materials. Adjusting the procurement point is necessary in such cases. | Excess |

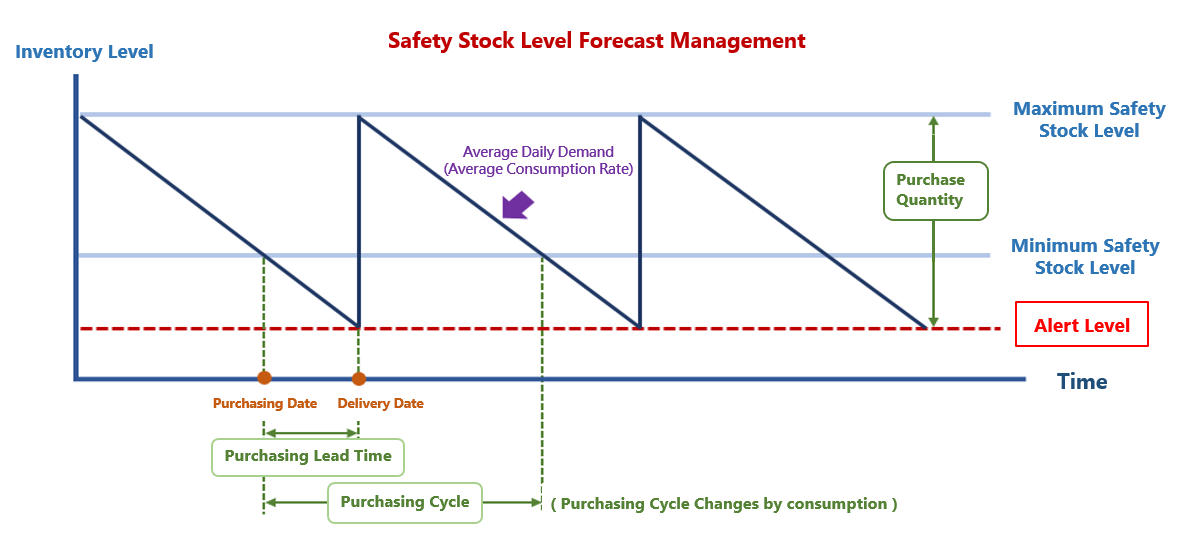

Indicator lights display abnormal inventory level conditions

Warning: Presented in a signal light status.

⚑A red light indicates below and above inventory levels.

⚑A yellow light indicates that the short to medium-term forecast predicts insufficient supply and current capacity cannot meet demand.

⚑A green light indicates that the inventory level is within the normal range.

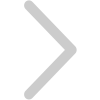

iTEC ERP intelligent inventory management

- Offering dynamic inventory levels

- Providing real-time inventory

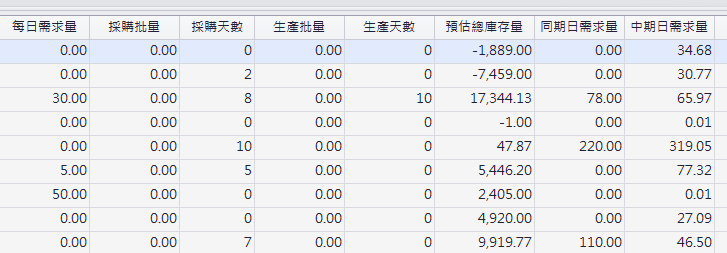

- Supplying inventory forecasting analysis

- Offering reorder points

- Prioritizing lead times for critical components and synchronizing level adjustments.

- Adjusting inventory levels synchronously based on changes in procurement or production lead times

- Adjusting inventory levels synchronously based on fluctuations in market demand

- Adjusting inventory levels synchronously based on changes in product marketing strategies

- Providing dynamic inventory levels

- Utilizing big data analysis to continuously forecast and analyze past and future (short, medium, and long-term) inventory levels.

Related Information

How to rapidly consolidate the financial accounts of multiple companies within a group?

How to manage frequent engineering changes (ECO/ECR/ECN) effectively?

ERP operational model in different industry?

Breaking News

Previous Article

Previous Article