CRM (Customer Relationship Management), POS (Point of Sale), WMS (Warehouse Management System), Automated Warehousing, Food Cloud, E-commerce, Electronic Invoicing, and more.

Including inventory, accounting, carbon account, and more.

Encompass the following module: Procurement, sales, inventory, inbound and outbound processes, returns and exchanges, inventory counting, adjustments, transfers, assemblies and disassemblies, borrowing, allowances...etc.

1. Identify items, 2. Fixed location, 3. A certain amount, 4. Specified container, 5. The standard layout, 6. The assigned person in charge. After implementing APS (Advanced Planning and Scheduling), the seventh principle "Regular time" can be added to achieve real-time dynamic inventory accuracy.

Reduce human errors in manual operations and improves the accuracy of inventory accounting.

Using barcode scanning to decode deductions, coupled with ERP for inbound and outbound documents, reduces personnel errors and improves accuracy and timeliness.

First and foremost, it is important to have warehouse and storage location functionality. This includes the ability to set up inventory tracking based on dependent demand or the first-in, first-out (FIFO) method. The system should be capable of automatically and intelligently deducting materials, avoiding the accumulation of stagnant inventory and achieving precise material preparation.

Prevent input errors in documents by personnel and enhance error prevention measures. Features such as alert notifications can be implemented. For example, alert notifications can be set up for situations such as item over-receipt, or inventory levels falling below or exceeding inventory level.

The ERP system provides functionality for the allocation of responsibilities based on the needs of the organization, emphasizing the principle that warehouse personnel are responsible for quantity management rather than price.

For multi-company organizations, it is essential to have the functionality to cross-check inventory across companies in order to improve product turnover rate and prevent loss of orders due to hoarding information.

Inventory is crucial for the short, medium, and long-term estimation of a business. Therefore, inventory management must have the capability to manage current inventory levels, work in process inventory, and forecasted inventory levels. This helps prevent stockouts and excessive inventory in warehouses, achieving optimal supply-demand balance in inventory management.

The system is equipped with intelligent calculation methods to facilitate predictive management of inventory levels. The system automatically generates timely notifications for supply-demand imbalances such as stockouts or excessive inventory. This helps ensure prompt awareness and action regarding any issues related to inventory levels.

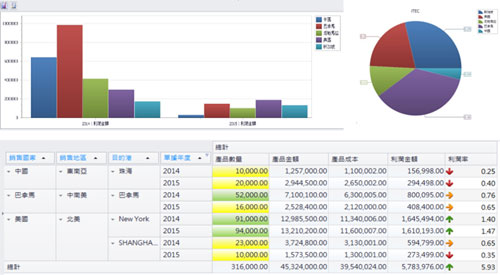

regional sales strategies

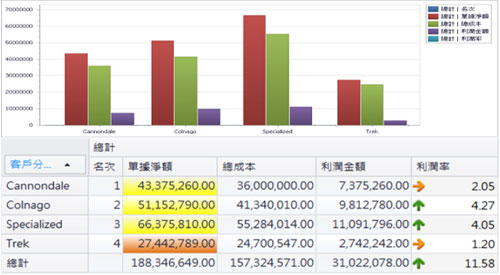

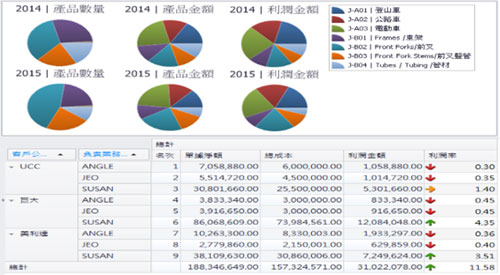

Providing big data analysis and decision-making reports, organizing massive amounts of data for analysis from various perspectives, and replacing reliance on experience. It presents information visually to assist in decision-making and provide predictive and alert information. By leveraging data empowerment, it accurately interprets the business value within the data.

brand marketing campaigns

Providing various real-time monitoring dashboards to gain insights into current warehouse demand and identify any shortages, enhancing stock shortage alert functionality.

customer relationship information

Inventory management should achieve alignment between physical and accounting inventory, enabling dynamic inventory tracking. This facilitates parallel operations between logistics and information flow, ultimately improving inventory accuracy and enhancing forecasting precision.

The warehouse should have classification management to categorize and manage different attributes and product grades.

It is necessary to integrate quality control, where all items must pass inspection before entering the warehouse, adhering to the principles of lean management and preventing defective products from entering the manufacturing or retail environments.

Once the inventory is closed, it should be locked and controlled to avoid discrepancies between inventory records and accounting records.

Inventory documentation should be transitioned to paperless operations, similar to the comprehensive electronic invoicing system.