iTEC ERP assists businesses in comprehensive digital transformation.

Before embarking on the journey of transformation,

it is essential to first change our mindset.

The expensive digital technology products purchased end up becoming digital relics that nobody uses.

Digital transformation must begin with a shift in mindset, company organization, and culture among personnel. Let iTEC ERP's professional coaches assist you in finding the right path for digital transformation.

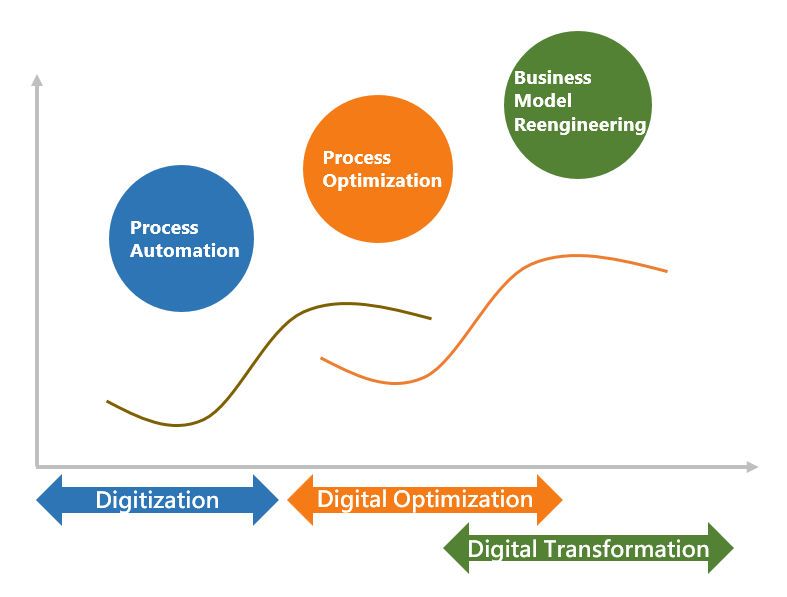

The three stages of digital transformation create new value for businesses.

Digital technology applications include information systems such as ERP(Enterprise Resource Planning), CRM(Customer Relationship Management), and MES(Manufacturing Execution System), as well as digital hardware devices.

Enhancing data applications, optimizing business processes, improving operational performance, and enhancing customer experience.

Mindset and cultural changes can lead to the creation of new competitive advantages and the development of innovative business models.

Digital Transformation-

The solution to address enterprise pain points

Annual transition to new product specifications with corresponding price reassessment management.

The current marketing methods are ineffective, and it is unclear which of the various attempted marketing approaches are effective.

Lack of familiarity or expertise in utilizing new online marketing tools.

Lack of understanding on how to effectively position the product has led to unclear market positioning.

The product lacks competitiveness while not knowing how to enhance its competitiveness.

Existing customers keep churning, but not knowing how to retain them. We can only focus on acquiring new customers.

Unavailable to reach out to existing client base, and don't know where they are.

Not knowing what the existing customers are lacking and what products to sell.

Not knowing which tools to use to maintain relationships with existing clients.

Product development cycles are too long and lack a clear deadline.

The absence of a production scheduling system leads to frequent issues such as downtime and material shortages during production.

Poor quality control and low yield

Excessive raw material inventory and excessive finished goods inventory result in a high capital backlog, making it difficult to realize cash.

Low customer order fulfillment rate, frequent customer complaints, and fines lead to low satisfaction, ultimately resulting in lost orders.

Unable to control scheduling and unaware of the production progress upstream.

Uncertain about the upstream's ability to deliver on time when facing material shortage issues.

Insufficient prediction accuracy, unaware of the demand level downstream.

Due to the lack of transparency in the overall supply chain, it is impossible to know the supply status upstream and downstream, resulting in an inability to respond promptly.

Different perceptions lead to increased communication frequency and low timeliness, resulting in increased complexity in overall operations and decreased problem-solving capabilities.