Customized ERP for the Bicycle IndustryCustomized ERP for Bicycle Assembly Plants/Frame Manufacturers/Component Suppliers

Ten Key Demands of Bicycle Assembly Plants

1

Annual replacement of new product specifications and management of corresponding unit price reassessment.

2

To meet the needs of the bicycle assembly plant, it is necessary to establish a critical parts safety stock (Customer-specific and shared parts).

3

To cope with the short lead time requirements of the bicycle assembly plant, it is necessary to have highly flexible scheduling and adjustment management between the forecasted demand and actual orders. This will help achieve optimized supply chain responsiveness to meet the requirement effectively.

4

The comprehensive barcode and QR code management of products.

5

Integration of accounts receivable with complete order payment mode for streamlined accounting and auditing.

6

Real-time dashboard situation management provides comprehensive visibility into inventory levels, production progress, exception alerts, and statistical analysis.

7

Using bike serial numbers (beneath the bottom bracket) enables quick traceability of product manufacturing history.

8

Real-time and accurate cost management allows for the immediate presentation of the production cost for each order batch.

9

Annual new product development project management includes sample development, cost control, and project management.

10

Digital management tools help transform traditional management practices into scientific and data-driven operations by accurately quantifying key performance indicators.

Top Ten Key Demands of Component Manufacturers

1

Procurement points of crucial components such as transmission kits and safety stock (Customer-Specific and shared parts) control.

2

Challenges of production schedule: "How to respond to frequent product changes and significant variations in delivery time."

3

Bottlenecks in production scheduling: supplier lead time and quality (such as Frames and Forks) → Resulting in order non-fulfillment

4

Control inventory levels and avoid the risk of shortages or production stoppages.

5

Can the production and sales platform provide real-time and efficient information to respond quickly to the challenges on site?

6

How do we accurately determine the minimum inventory level for achieving a demand-supply balance?

7

Real-time dashboard situation management provides comprehensive visibility into inventory levels, production progress, exception alerts, and statistical analysis.

8

Using bike serial numbers (beneath the bottom bracket) enables quick traceability of product manufacturing history.

9

Real-time and accurate cost management allows for the immediate presentation of the production cost for each order batch.

10

Annual new product development project management includes sample development, cost control, and project management.

iTEC ERP Meets The Requirements of The Bicycle Industry Chain

Advanced Planning and SchedulingIntelligent planning for production scheduling and improving order fulfillment rate.

The Best Strategic Partner for the Bicycle Industry– iTEC ERP

Multiple versions of the Bill of Materials (BOM)

- To meet the diversified clients' demands, provide multiple versions of the same product's Bill of Materials (BOM) and create different versions based on various requirements such as sampling, mass production, packaging, and formulation to fulfill the needs of each department.

- Designing and producing multiple versions corresponding to the same product can be done simultaneously, avoiding the need to create numerous part numbers.

Estimation Order Management

- The MPS schedule is allocated and used according to the customer's designated estimation orders.

- The clients→Designated estimation orders→Production schedule MPS allocation and access.

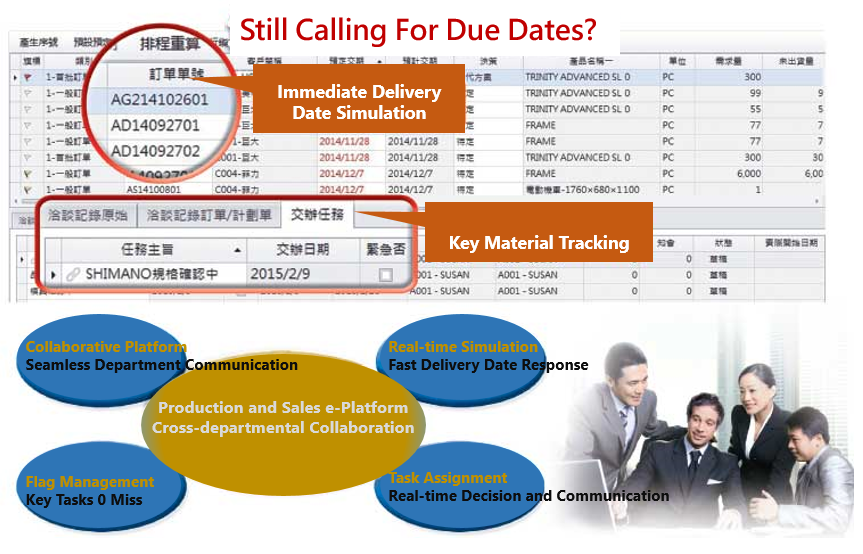

Production and Sales Communication Platform

- Electronic production and sales communication platform enables cross-department collaboration.

- Unified platform: Seamless communication across departments.

- Flag management: No missing vital tasks.

- Real-time simulation: No waiting for delivery dates.

- Assigned tasks: Zero communication delay in decision-making.

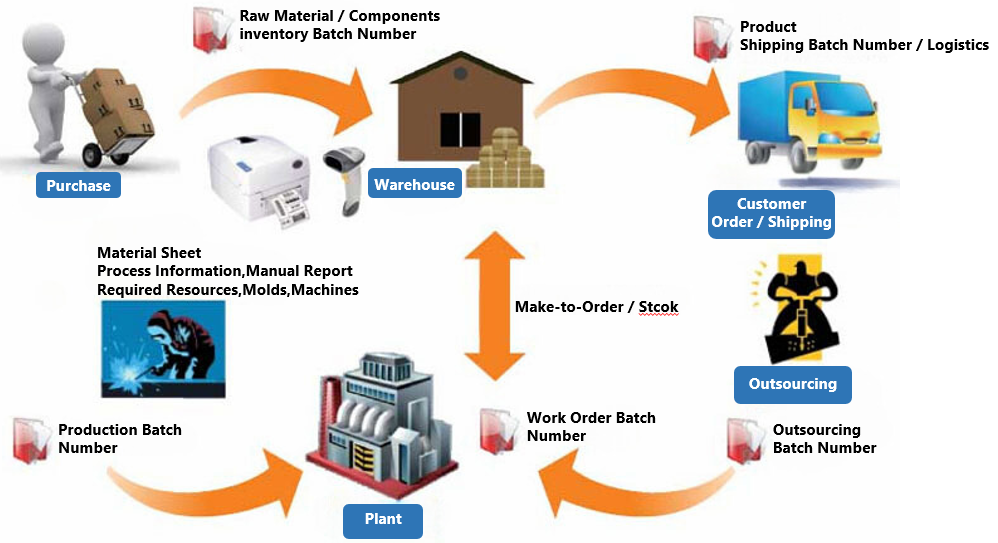

Comprehensive Barcode Implementation

From receiving and issuing materials, outbound delivery and inbound delivery, production reporting, warehouse stocktake, purchasing, and shipping, the comprehensive adoption of barcode management reduces error rates and improves work efficiency.One-stop Multilateral Trade

- Multilateral trade integration platform

- Quick order dispatch/Integrated audit

- Save more than half of the operation time

Production Traceability

The production history of products can be traced through "production batch numbers" or "Bike serial numbers," including complete records of material suppliers, incoming inspections, subcontractors, work centers, IPQC/FQC, and other production processes. It also provides batch cost and production efficiency analysis information.ERP Production Progress Dashboard

From order acceptance to scheduling, procurement, material preparation, material issuance, various production processes, and completion and inventory entry, real-time monitoring ensures timely order fulfillment.Affirmation of expertise from the client. Appreciate the following clients for choosing iTEC-"Bicycle Industry-specific ERP software."