Warehouse Management System(WMS)

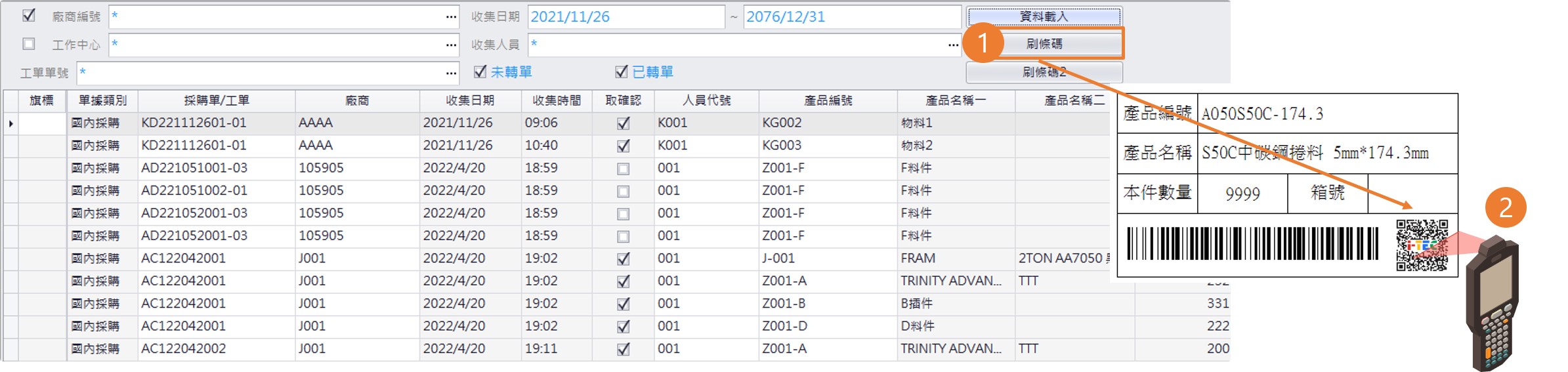

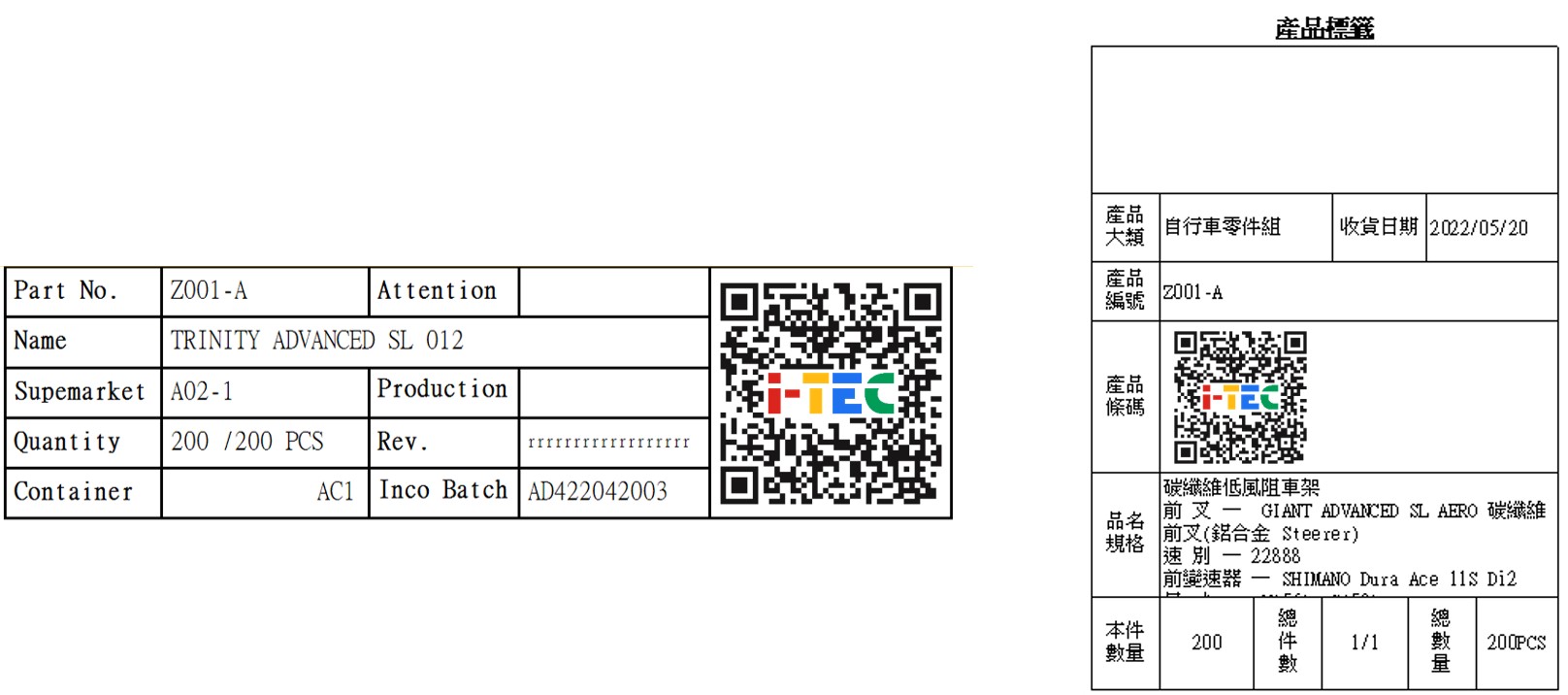

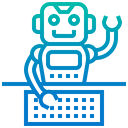

Receipt

During the process of receiving materials, confirm the receipt information by scanning the barcode, thus reducing manual receipt errors.

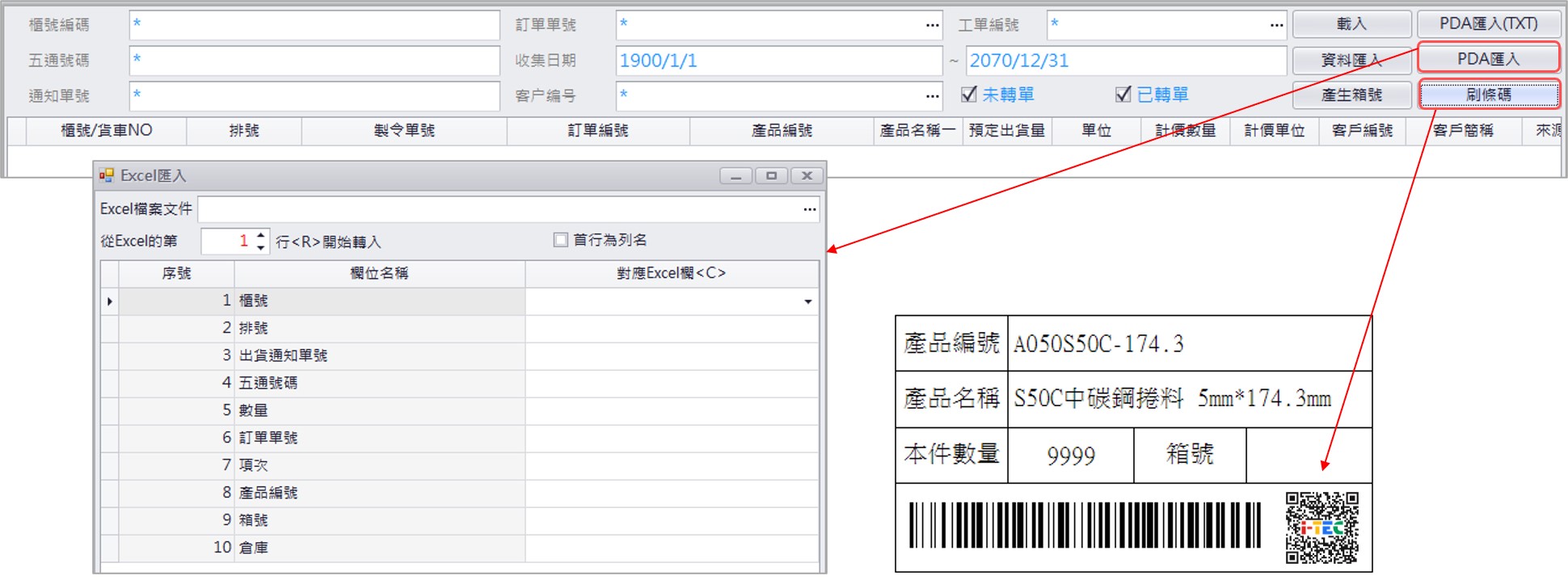

Transfer

During the process of transfer, accurately reflect and record the inventory changes of each batch of materials by scanning the barcode.

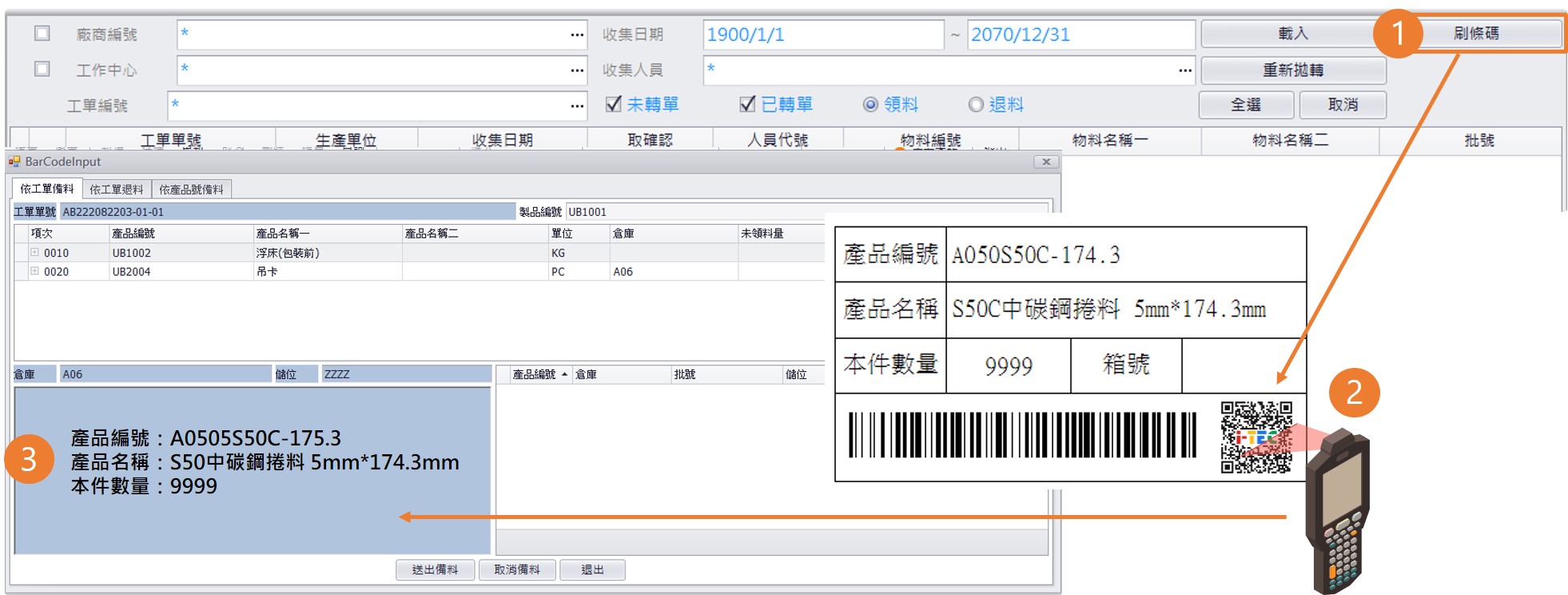

Withdrawal

During the material withdrawal process, scanning the barcode enables quick determination of the accuracy of material retrieval.

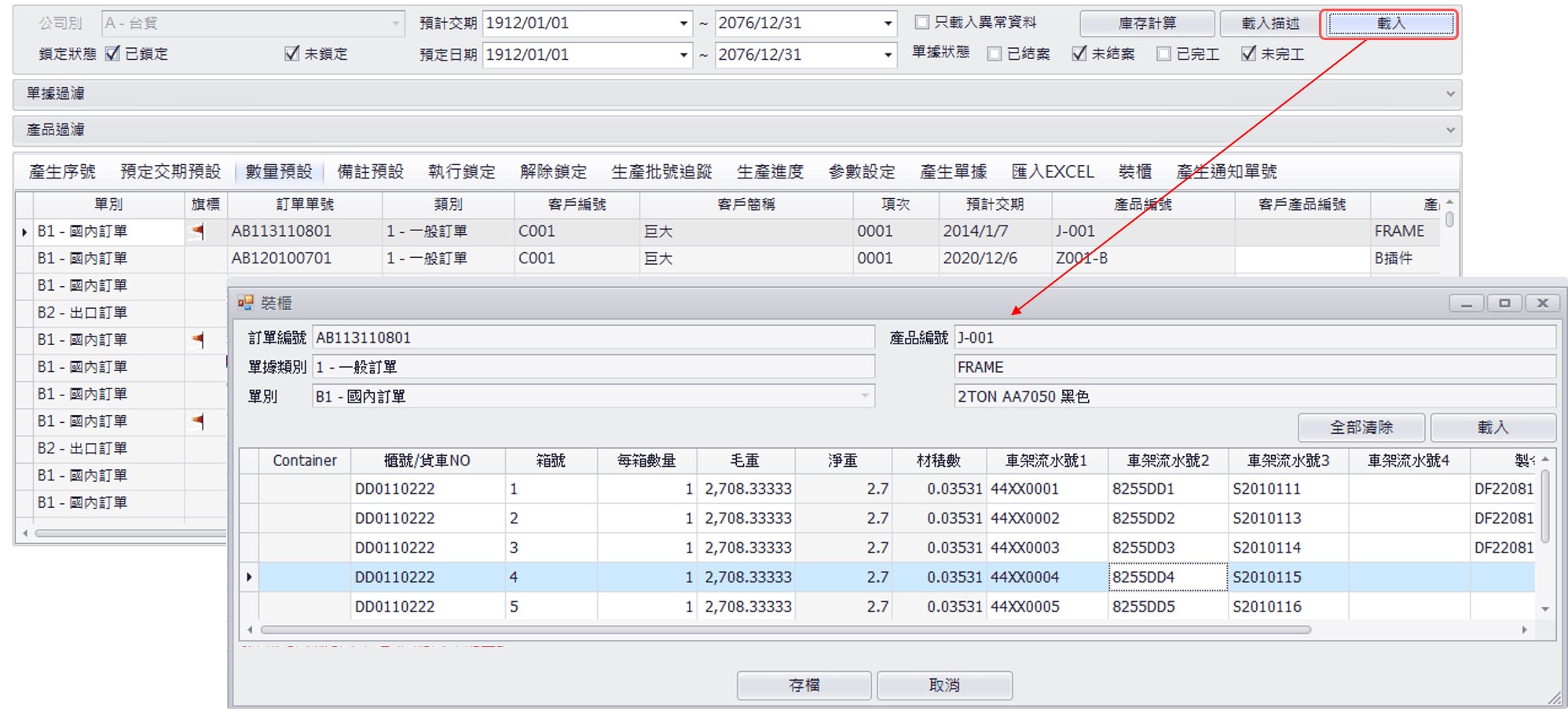

Container loading

Through barcode scanning during container loading, the actual recording of the packing status for each product serial number is accomplished.

Warehouse Management System (WMS) Workflow

Benefits of Barcode WMS

Barcode management facilitates a transformation in company management, shifting from traditional experiential management to precise information-based management. Utilizing tools for real-time feedback and reducing error rates enables the supply chain to be accurate and timely, ultimately enhancing the overall competitiveness of the enterprise.

Reducing manual data entry helps decrease the rate of human errors.

From product receipt to shipment, a first-in, first-out (FIFO) approach is followed, and storage batch numbers are assigned. This precise management, coupled with intelligent error prevention, enhances work efficiency and minimizes human errors.

The product logistics tracking process is traceable, ensuring traceability.

By implementing automated data collection, full traceability is achieved throughout the entire product workflow.

Real-time information enables the monitoring of inventory status.

By maintaining real-time visibility of inventory status, businesses can effectively manage and control their inventory levels.