Characteristics of Concurrent Design and Production

1

Frequent specification changes

2

Rapid specification changes

3

Long cycle time

4

Difficult inventory control

5

Difficult control of multiple part numbers

6

Low-volume, high-variety production

7

High customization rate

8

High technical barriers

9

High difficulty in quality control

Do you have the following questions?

1

How to modify a purchase order that has been placed?

2

How to modify received goods?

3

How to modify materials that have been issued?

4

How to modify products that have been produced?

5

How to handle excess inventory?

6

How does schedule modification work?

7

How to handle a large volume of change orders manually?

8

How does coordination with suppliers work for issued purchase orders?

Intelligent Change Management Platform

Intelligent Change Management Platform

- Provide functionality for adding/removing/revising components in ECN (Engineering Change Notice) operations.

- Manage change approval process.

- Real-time updating of BOM (Bill of Materials) structure.

- Enable order change initiated by the sales team.

End-to-End Change Trigger

End-to-End Change Trigger

- Synchronously and automatically generate work orders and purchase order changes

- Perform audit checks on completed documents.

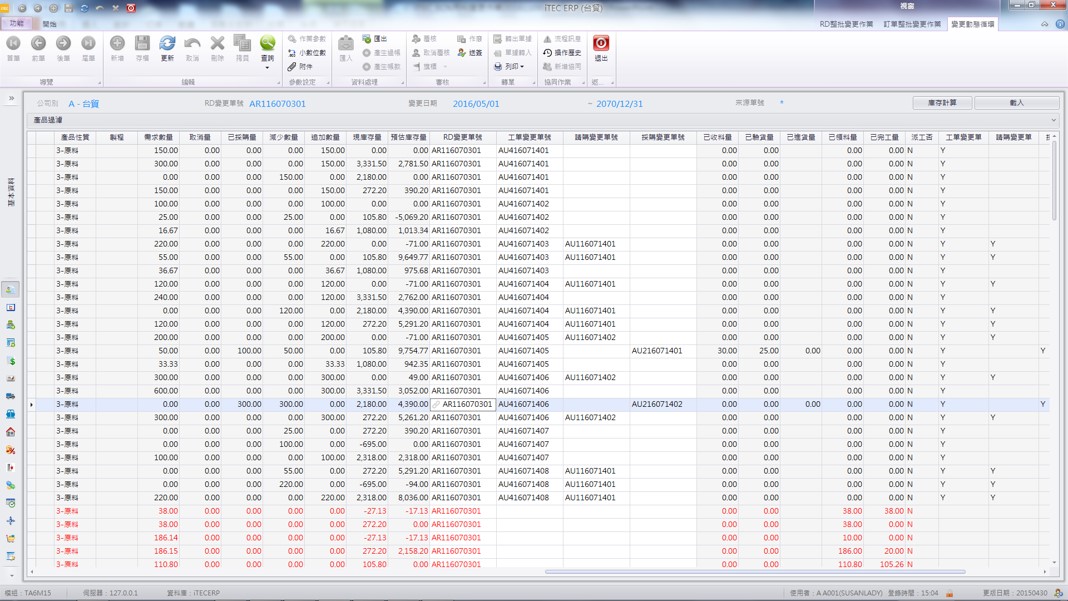

Dynamic Analysis Platform for Design Changes

Dynamic Analysis Platform for Design Changes

- Track the number of changes for raw materials within a specific range.

- Track the number of changes for products within specific ranges.

- Track the number of changes for a specific order.

- Perform change responsibility attribution analysis.

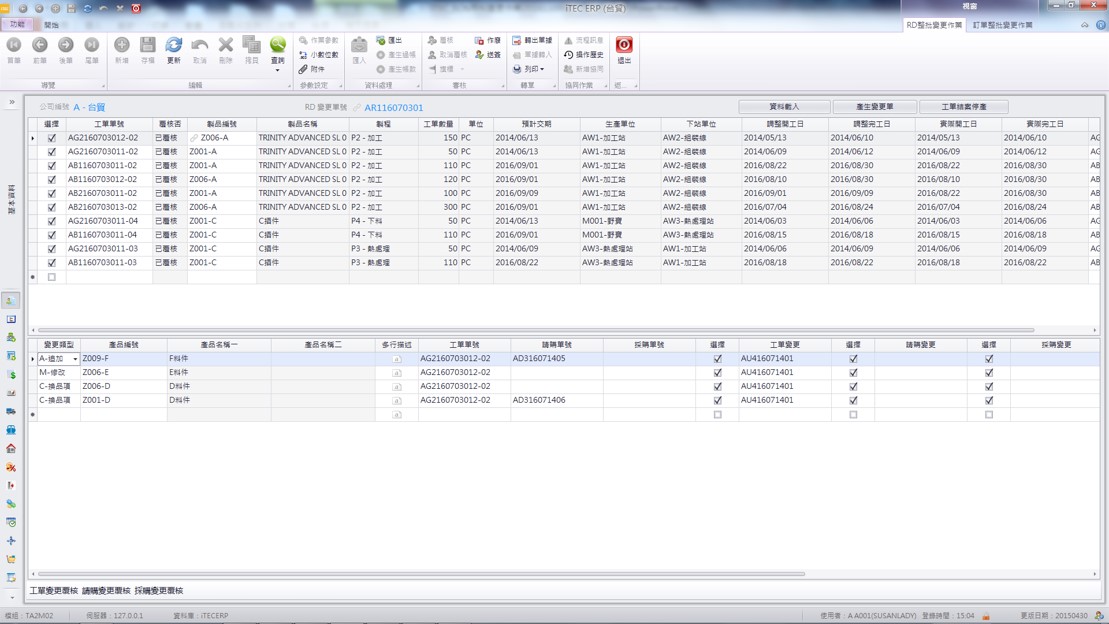

ECN (Engineering Change Notice)

What problems are you encountering?

1

How to achieve accurate communication and quick problem-solving when designing and producing simultaneously?

2

How does the operation work when there are no immediate manual operations generated by automation?

3

Frequent occurrences of missed procurement or missed material changes in work orders result in materials that should have arrived not being received, while those that should not have arrived did.

4

The increasing amount of stagnant inventory is causing a lot of trouble. How can it be improved?

| Change Order Types | Approaches | Reviewing Unit |

| ➀ Change BOM & Order | For the specified change order, update the corresponding work orders and procurement/purchase orders. | Sales/Production Planning/Purchasing |

| ➁ Change BOM | For the specified part number, modify the BOM (Bill of Materials) | Sales/Production Planning/Purchasing |

| ➂ Change Order | For the specified order, modify the corresponding work orders and procurement/purchase orders. | Sales/Production Planning/Purchasing |

End-to-End Change Trigger

Dynamic Analysis Platform for Design Changes

Benefits of Concurrent Design and Production

When a material change process is initiated by R&D, the system automatically generates relevant change orders through the R&D batch change process.

After the change orders are reviewed and approved, the system automatically updates the corresponding documents, creating a comprehensive historical trail.

Periodic inventory audits or intelligent inventory analyses can be conducted to determine the quantity of aged inventory that can be substituted or has exceeded the specified days.

The data related to changes can be analyzed to assess the cost of failures caused by the changes.