ERP Knowledge Base

How to manage frequent engineering changes (ECO/ECR/ECN) effectively?

Features of Concurrent Design and Manufacturing

1

Rapid specification changes

2

Multiple specification changes

3

Long production cycles

4

Difficult inventory management

5

Managing numerous product codes

6

High customization rates

7

Low volume, high variety production

8

High technical barriers

9

Challenges in quality control

Problems of Concurrent Design and Manufacturing

1

How to handle excess inventory?

2

How does the production scheduling work for changes?

3

How to process a massive volume of change orders manually?

4

How to coordinate with suppliers for changes when orders are already placed?

5

How to make changes to already purchased materials?

6

How to handle changes when goods have already been received?

7

How to handle changes to materials that have already been issued?

8

How to handle changes to products that have already been produced?

How to manage concurrent design and manufacturing?

Intelligent Change Management Platform

- Providing ECN(Engineering Change Notice) change operations for adding/removing/replacing/modifying components.

- Change approval process

- Updating the BOM (Bill of Materials) structure table in real time.

- Initiating order changes from the sales representative

Triggering an end-to-end change process.

- Automatically synchronize the generation of work orders and purchase order changes.

- Conduct audits to check completed documents.

Change Dynamic Analysis Platform

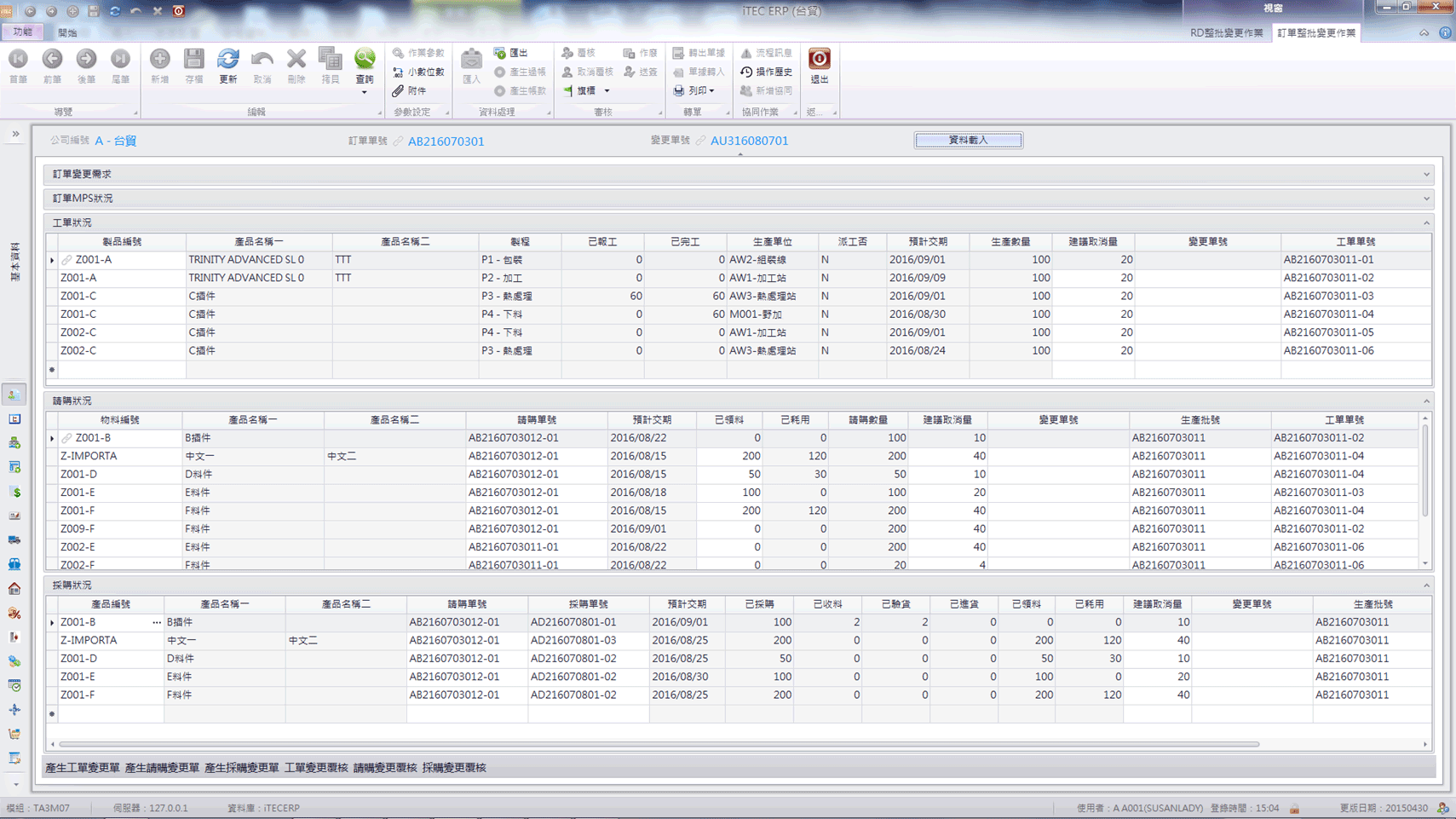

- Provide the number of material changes within a specific range.

- Provide the number of product changes within certain intervals.

- Provide the number of changes for a particular order.

- Analyze change responsibility attribution.

Operational Issues in Practice and Improvement Directions

1

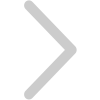

When R&D initiates material change operations through batch processing, the system automatically generates related change orders.

2

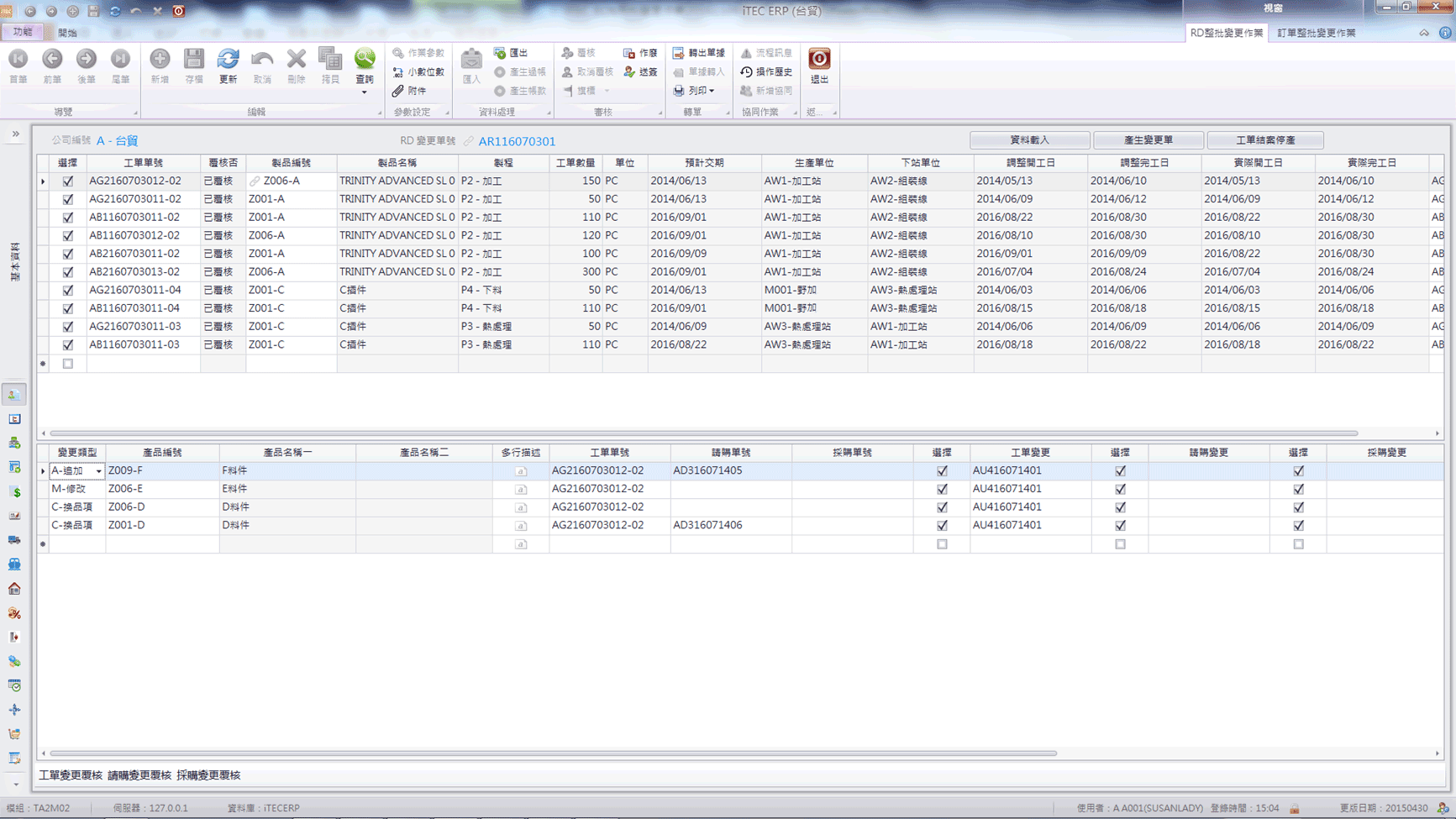

After change orders are reviewed, the system automatically updates and adjusts the documents, creating a comprehensive historical trail.

3

Regularly auditing inventory or utilizing intelligent inventory analysis to determine when quantities with an age exceeding a certain number of days can be replaced.

4

Analyzing the cost of failures caused by statistical change data.

5

Using statistical data on changes from various perspectives such as customer, order type, product type, etc., as a basis for improvement.

Related Information

How to rapidly consolidate the financial accounts of multiple companies within a group?

ERP operational model in different industry?

How to manage complex and frequently changing materials?

Breaking News

Previous Article

Previous Article