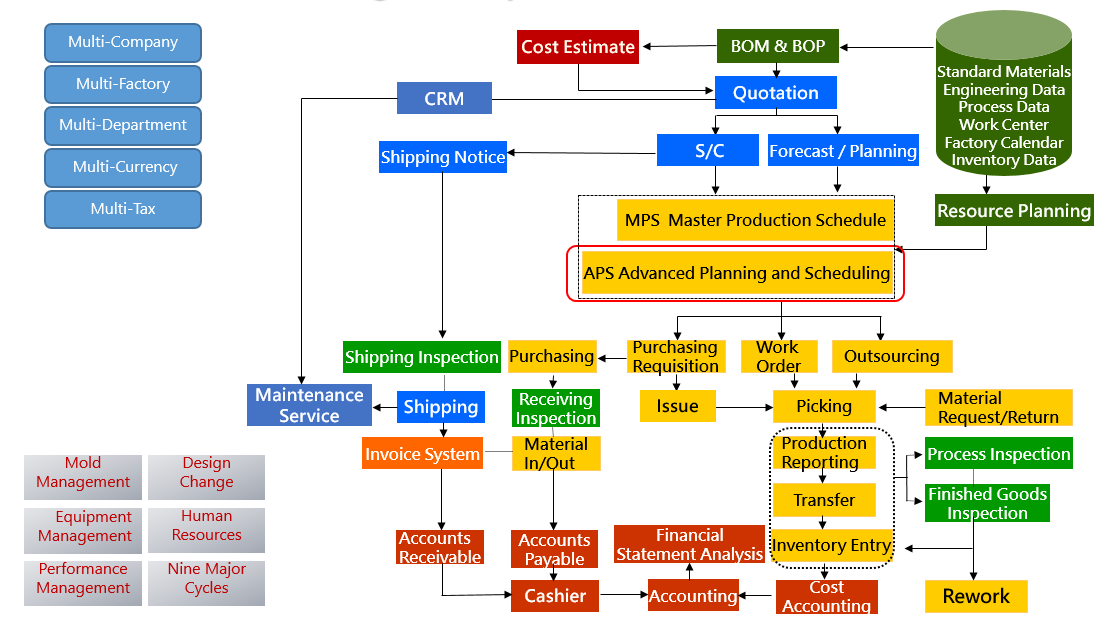

Advanced Planning and Scheduling (APS)

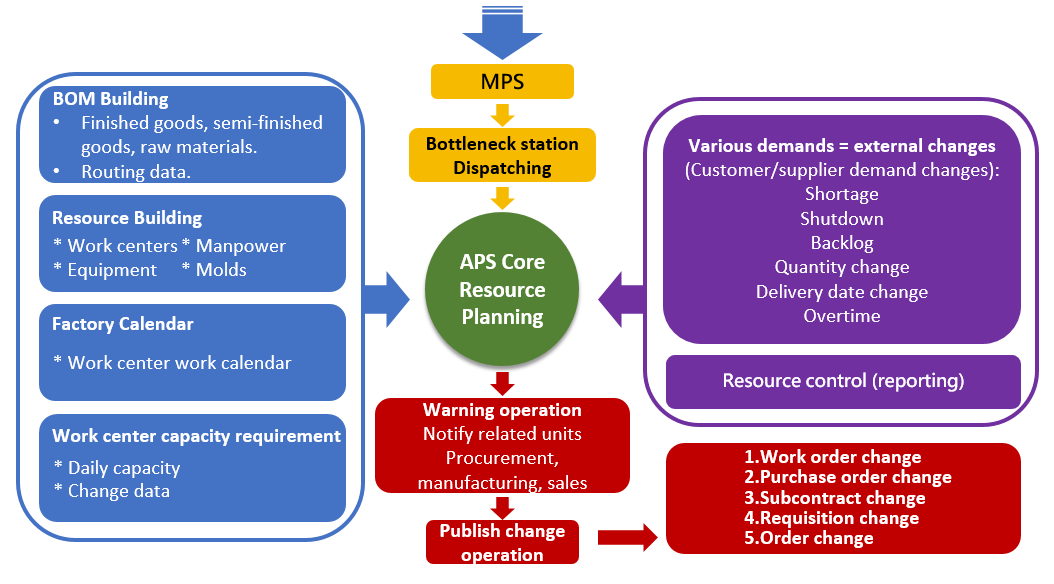

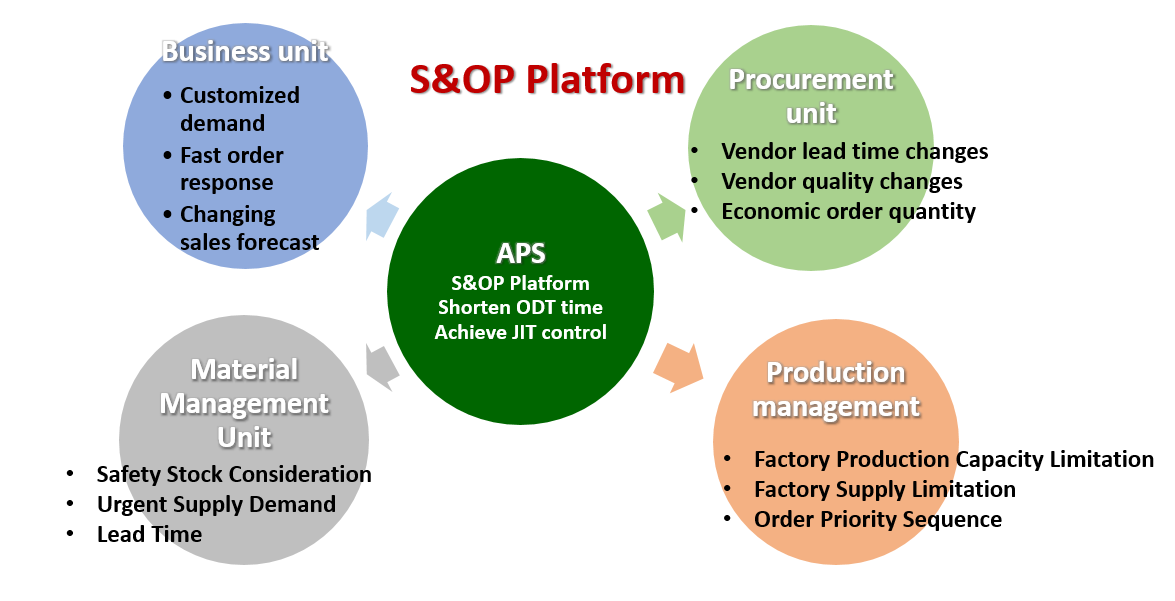

Advanced Planning and Scheduling (APS) is an advanced planning and scheduling tool based on supply chain management principles and constraint theory. It utilizes advanced algorithms to achieve a dynamic balance between "materials" and "capacity" considering the limited resources of the enterprise. APS provides effective and accurate production scheduling and planning, enabling quick response to customer inquiries and delivery dates, reducing order-to-delivery (OTD) time, lowering production and inventory costs, and improving delivery performance.

Do you have the following questions?

1

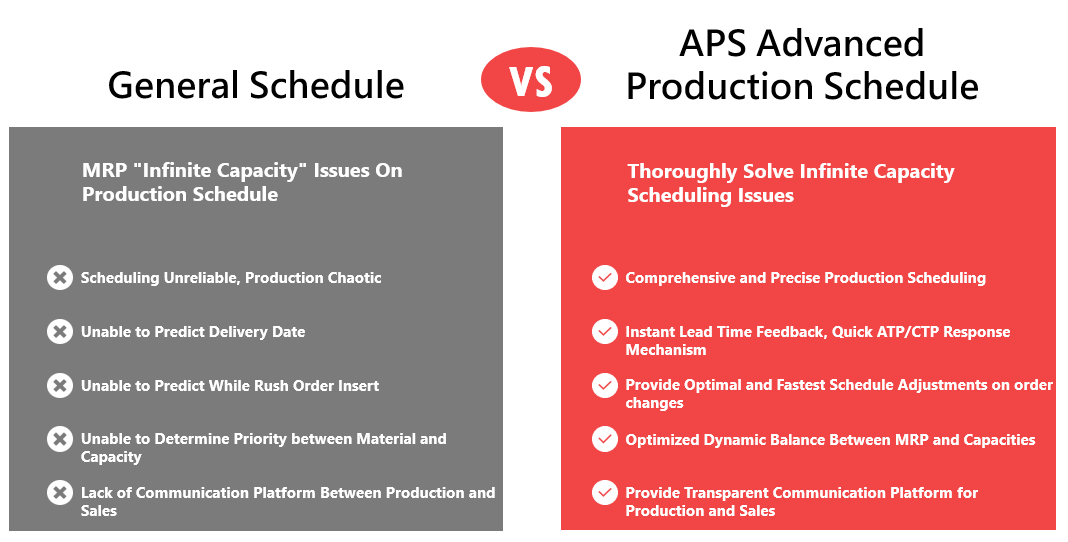

The schedule is unreliable, production is chaotic, and the production plan scheduled in advance is always difficult to implement!

2

It is unable to predict how much the remaining order quantity can be promised.

3

It is unable to predict whether the customer's required delivery dates can be achieved.

4

Unable to predict whether rush orders can be inserted, and the impact of accepting rush orders on existing orders.

5

Unable to assess whether optimal capacity utilization can be achieved while meeting the delivery deadline.

6

Unable to determine whether capacity or material prioritization should take precedence during scheduling.

7

In the case of full capacity utilization, it is unable to automatically search for alternative processing and alternative production routing.

8

How can production schedules respond quickly when customers and suppliers undergo frequent changes?

9

Is the molds and jig allocation smooth?

10

Production and sales have their perspectives and lack a communication platform.

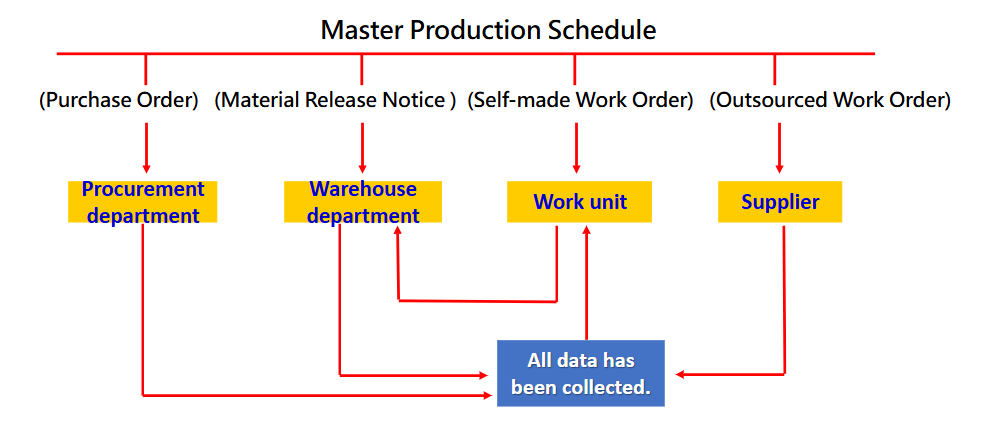

APS Core Resource Planning

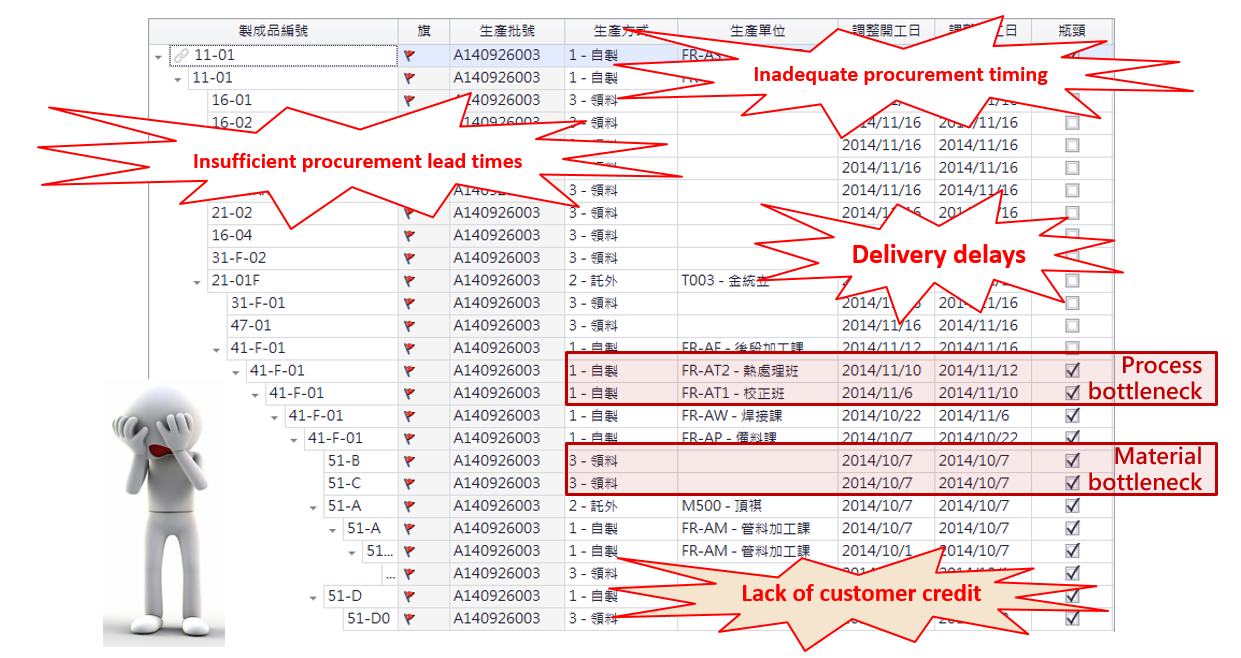

The Most Challenging Problem For Businesses

"Three No's and One Lack."

"Three No's and One Lack."

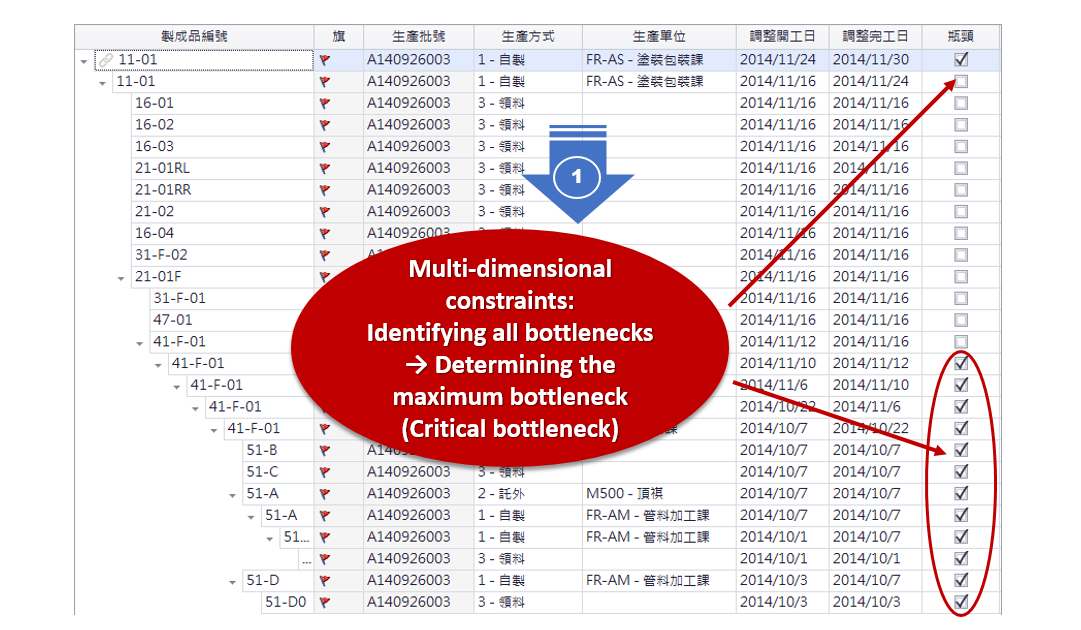

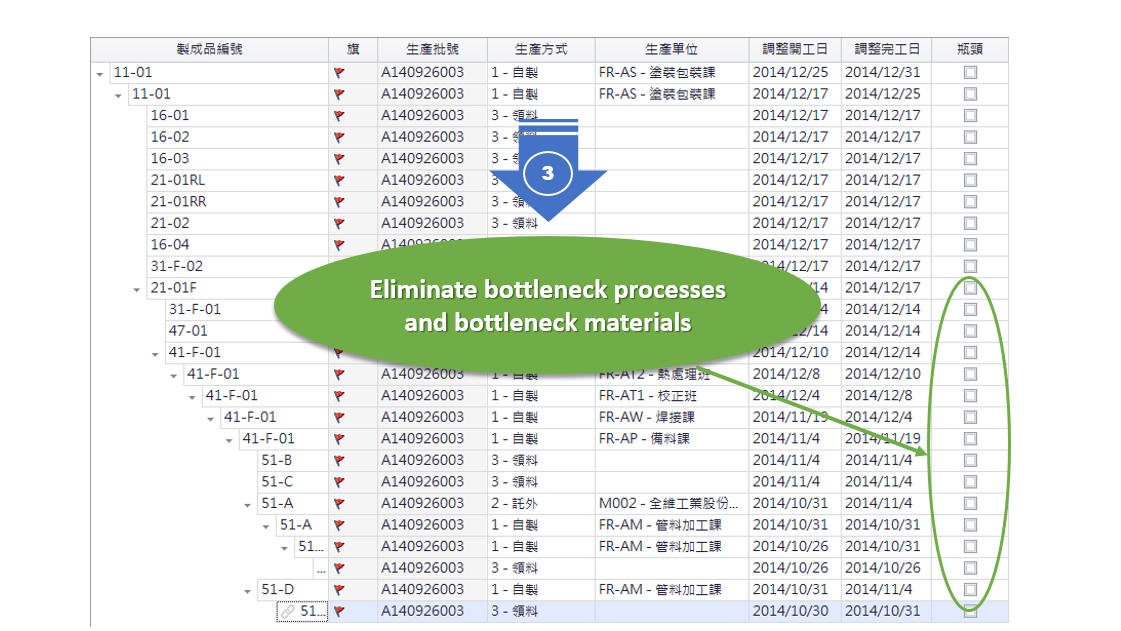

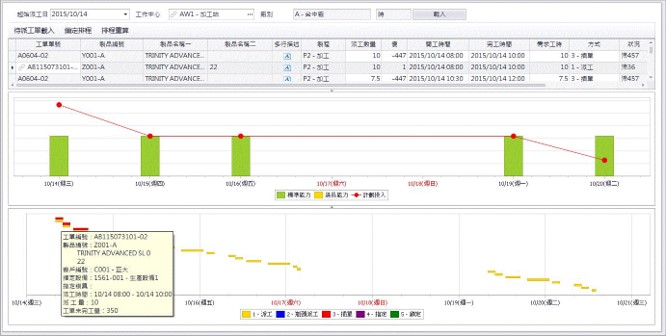

APS Core engine: Identify Key Bottlenecks and Adjust

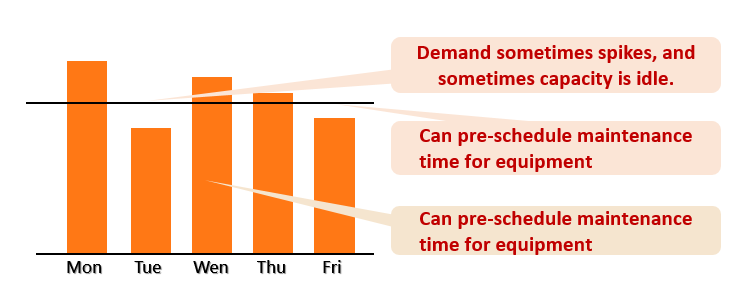

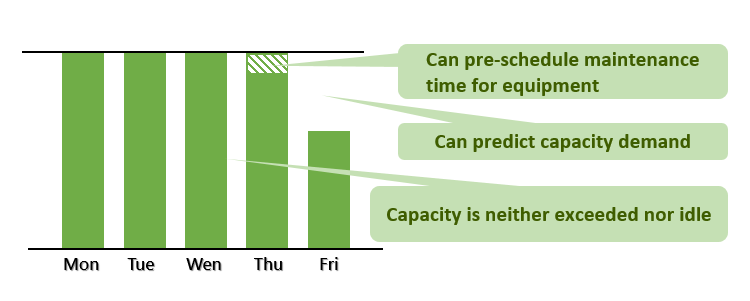

APS Dispatching Rules: Capacity Leveling

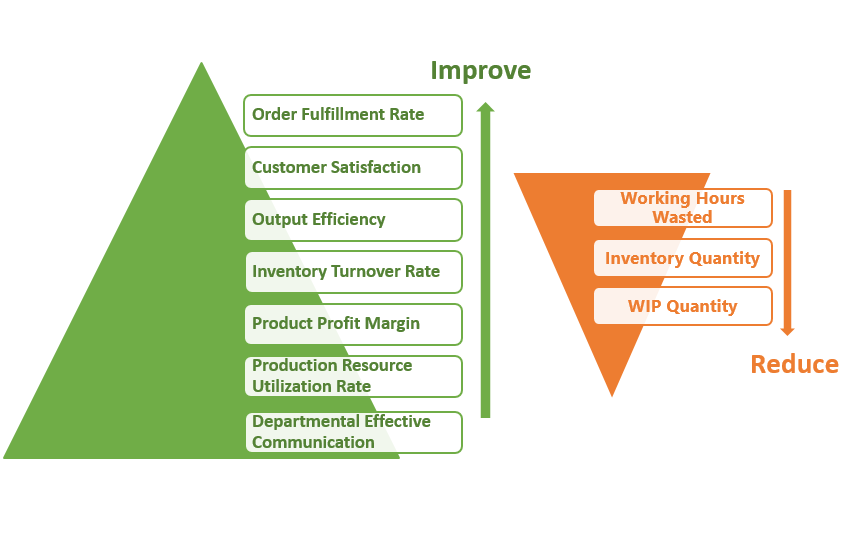

The improvement of multiple KPIs is derived from APS.

The overall efficiency of the factory.

Efficiency improvement of individual machines or production lines

The results are far inferior to

those produced by the production scheduling plan

APS acts as a mediator to resolve conflicts and promote effective communication among departments