How to manage complex and frequently changing materials?

Factors Affecting Procurement Lead Time

Internal Factors

- Changes in customer orders.

- Supplier lead time delays.

- Poor quality of incoming materials.

External Factors

|

|

|

|

- Provide the capability to adjust multiple lead times rapidly while preserving revision records simultaneously.

- Offer material tracking prioritization for determining production sequencing decisions.

- Implement 80/20 theory analysis for managing production schedules, and prioritize critical materials to meet production schedules first.

- Utilize a big data database for forecasting mid to long-term inventory estimates in the future.

- Trace materials according to orders.

- Provide a list of orders affected by revised lead times, showing the difference in delivery days.

- Offer real-time dynamic material tracking analysis.

Feature Highlights

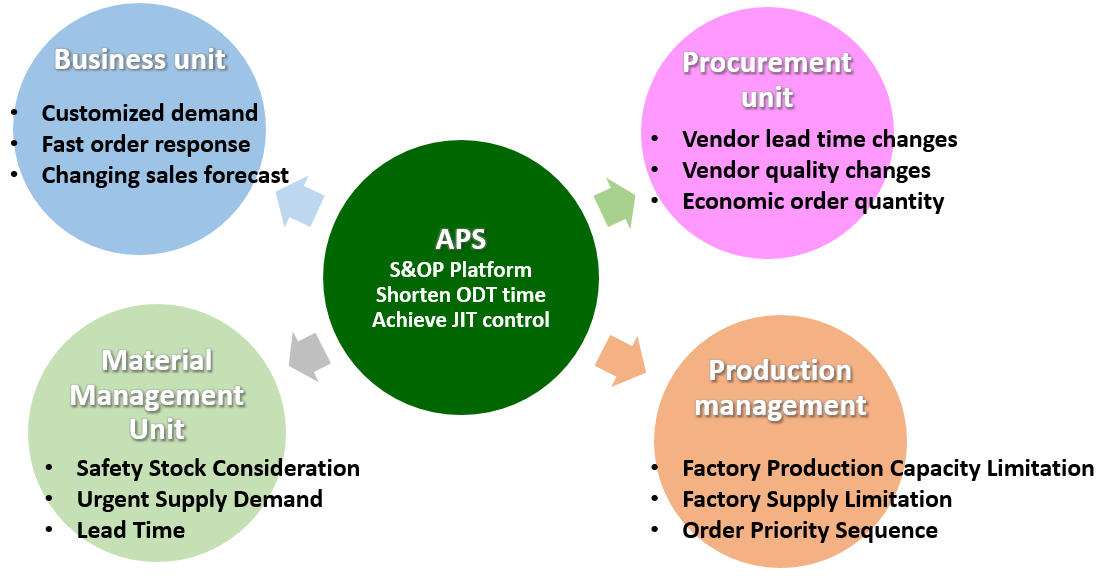

Demand and Supply Process

i-TEC ERP APS

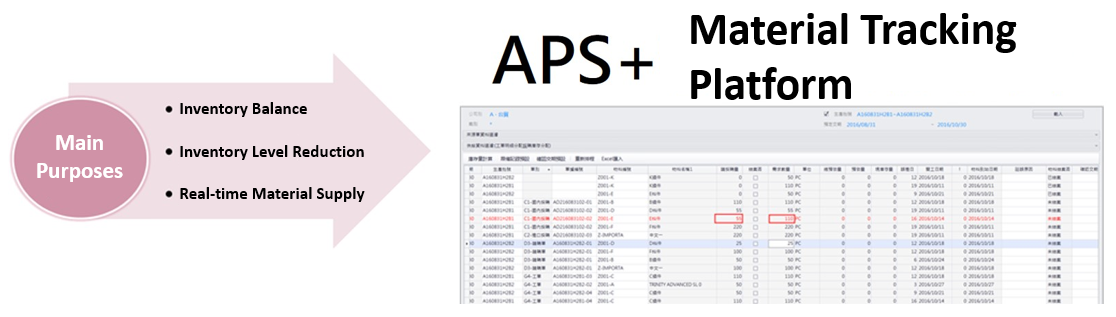

Become a peacemaker in departmental communication conflicts.

Utilizing advanced algorithms, we optimize scheduling and efficiently balance supply and demand for "materials" and "production capacity" while considering the company's limited resources. This enables swift responses to customer inquiries and delivery times (ATP/CTP), effectively reducing order-to-delivery (OTD) times, lowering production and inventory costs, and enhancing order fulfillment rates.

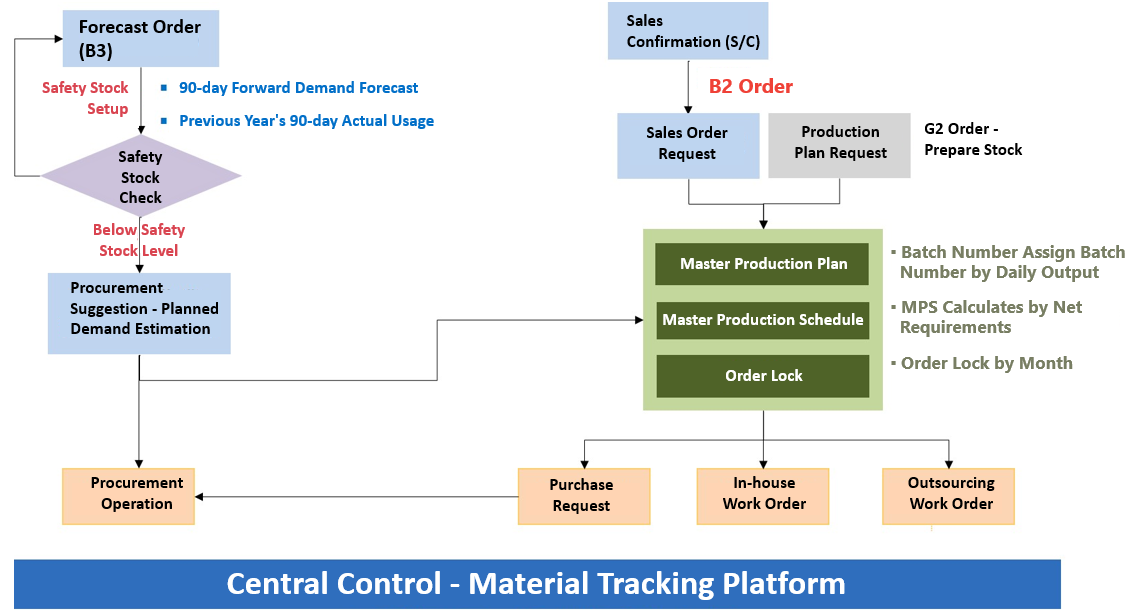

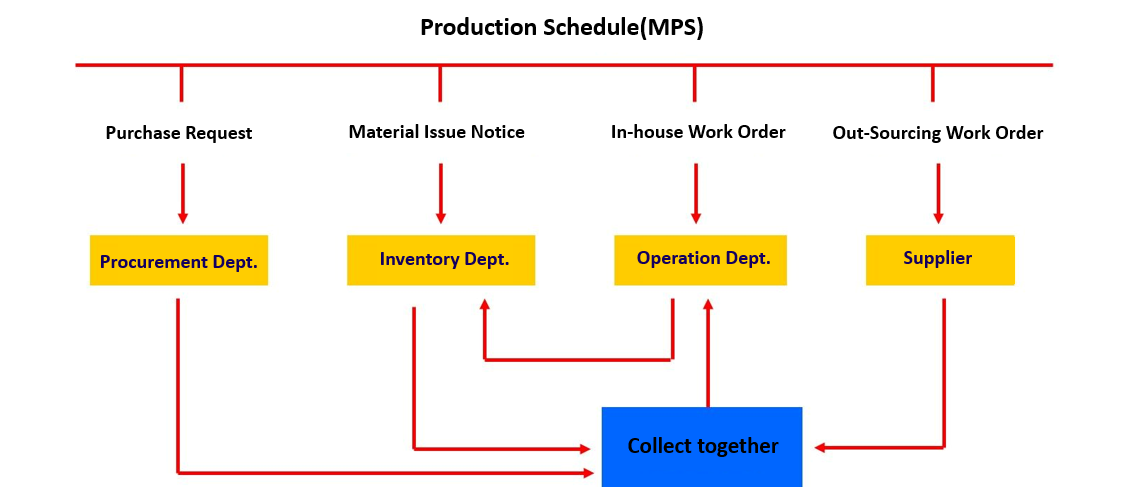

Material requirements planning should be carried out in phased tasks.

- MPS Scheduling → Procurement communicates and provides feedback on delivery dates.

- Locking order material tracking

- Supplier commitment to delivery date and material tracking.

- Material delivery date changes.

- Production schedule changes.

- Order delivery date changes.

- Predicting inventory to achieve supply-demand balance.

- Forecasting market demand.

Material tracking platform.

The exclamation mark"!" indicates a shortage of supplies alert.

- Red text indicates a shortage.

- Negative numbers indicate insufficient days.

"Error days" indicate a delay in the customer's delivery schedule.

- Red text indicates a shortage.

- Negative numbers indicate insufficient days.

"Simulation Scenario" provides immediate scheduling simulation.

- Red text indicates a shortage.

- Scheduling simulations can be conducted using critical materials.

- Scheduling simulations can be conducted using maximum delivery dates.

Analyze the material situation to determine whether the supply and demand for materials are optimized for inventory.

"Total Forecasted Quantity" for supply-demand balance analysis.

The excess inventory of materials (total supply minus total demand) is considered the estimated available quantity."Estimated Quantity" analyzes the forecasted inventory at demand points.

The excess inventory on the material work order's start date (supply minus demand) is considered the estimated available quantity on the start date.Current Inventory Quantity

The "Current Inventory Quantity" represents the quantity of materials currently visible in the warehouse. It serves as an immediate reference for determining availability when there's a need for an urgent order."Import Procurement" ship schedule planning

- The "Shipping Date" field can only be maintained for document type C2. If a shipping date is specified, the system will update it to the estimated export date of the import procurement order.

- Please determine whether this purchase order has already been transferred to another subsidiary company. When Company A's purchase order is converted into a document for Company B's sales confirmation, the sales confirmation is considered to have been converted into a purchase order.

- At this point, the shipping date should be updated directly to the "Estimated Export Date" on the purchase order without the need for calculations.

- For document type C2, the purchase confirmation should be automatically calculated based on the shipping date and the transportation days indicated in the diagram below.

The agreed-upon delivery date with the supplier can be confirmed and updated on the purchase order through EDI (Electronic Data Interchange).

"Delay Reasons" enhance management capabilities.

Why is it necessary to classify and statistically analyze delivery delays?"Excel Import" reduces the error rate of repetitive tasks.

The method of setting and updating the format."Supply and Demand" imbalance alert.

- When the item Z001-E on this work order has "Purchase Quantity < Demand Quantity," it should indicate in red text that the supply cannot meet the demand.

- So, it's necessary to verify if there is a stock withdrawal or allocation of the estimated order quantity.

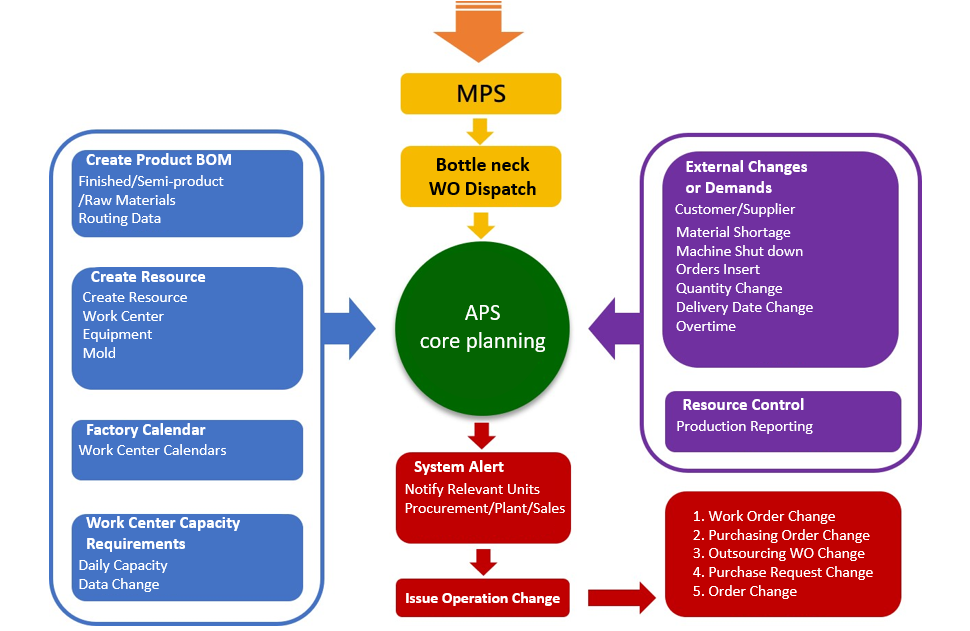

"Rescheduling"

Reschedule with the maximum bottleneck material delivery date to optimize the procurement plan, and record all materials that have been rescheduled.

- The MPS calculation time will schedule a recalculation based on the maximum date.

- In the dispatch operation, scheduling recalculation is performed according to this station.

- Production and sales platform reschedule based on the confirmed delivery dates from orders.

- There are two options for material tracking:

(1) If it's the current data, the scheduling estimation is done by fetching the maximum date and then updating.

(2) If it's all data, the scheduling is updated only for entries where the confirmed delivery date and shipping date fields have values.

※ When a critical material number is selected, it means that its delivery date is always unaffected by changes in other schedules. This operation must be performed by individuals with special privileges.

i-TEC ERP APS - An APS system embedded within an ERP

Previous Article

Previous Article