Simulate and calculate the material demand and productivity according to the order (S/C) while considering factors such as inventory, available quantity, on-order inventory, procurement batch, labor, machine capacity, etc., to calculate the estimated delivery date, and keep the simulated material demand and capacity temporarily stored, waiting for the customer to place an order.

During multi-layer processing operations, provide real-time query and corresponding inventory change details in multiple warehouses, on-site, and outsourcing manufacture.

At the work center or processing factory, according to the process transfer operation, generate the process warehousing order and the material requisition order at the same time, reducing the occurrence of repeated input and errors by manual labor and according to the production warehousing and entrusted warehousing orders, automatically write off the finished product and semi-finished product inventory of the work center or processing factory.

With "TPS push/pull management settings."

- Push process:

After completion at the previous station, it can automatically transfer the work in process inventory between work centers/production units to the next station. - Pull management:

It can control the material requisition mechanism, clearly distinguish between material movement and inventory ownership, implement "work in process inventory management operations," assist in the integrated inventory of materials throughout the factory, and provide real-time production progress display boards and light signal warning management.

Material control distinguishes between materials that can be overdrawn and those that cannot be overdrawn while providing query operations for general, on-site, and entrusted warehouses. It can query and control inventory, available quantity, and on-order inventory quantity separately.

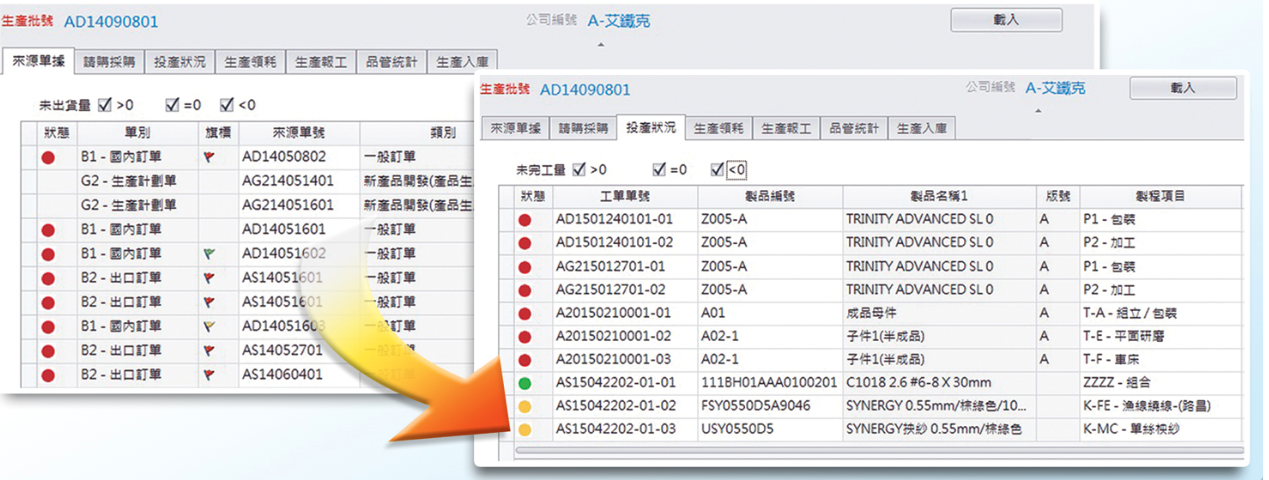

Combined with ERP to produce daily work reports, "dynamically presenting the latest production progress," and can be integrated with the MES manufacturing execution system.

Optimize the inbound and outbound process, improve warehouse efficiency, and keep track of the current inventory status in the warehouse/storage location in real-time.

Achieve 0 communication gaps between departments, 0 waiting for delivery date replies, 0 omissions of critical tasks, and 0-time differences in decision-making and execution.

Provide optimal scheduling planning, quickly respond to customer inquiries and delivery dates, effectively shorten the time from order to shipment (OTD), reduce production and inventory costs, and improve order delivery rate.

Provide a real-time dashboard for production and sales' best decisions and implement the purpose of achieving orders/production on schedule.

Through the production batch number, trace the complete production history and also provide batch cost and production efficiency analysis information.

Through the "batch change platform," intelligently generate corresponding change orders in batches to avoid supply and demand imbalances caused by excessive or insufficient inventory.

Perform "cost estimation" for products under development to accurately estimate business costs when quoting.

At the time of actual cost settlement, provide "multiple cost allocation methods," such as standard working hours, actual working hours, quantity, parent cost storage, etc.

For the total cost after the settlement of work-in-progress and finished products, provide "multidimensional cost analysis reports," such as unit cost table, direct material details table, standard and actual cost, standard and actual working hours, and standard and actual consumption difference analysis report.

- Meets international inspection standards:

With a complete incoming inspection IQC, process inspection IPQC, patrol inspection operations, and supplier evaluation mechanisms, it provides general inspection, sampling inspection, full inspection, and exemption methods to meet the flexible application of enterprises. - Quickly establish quality assurance standards:

To meet quality control applications, provide international MIL-STD-105D and 105E sampling standards, which can set different inspection standards and inspection items according to products and product categories, such as standard, strict, loose, and exceptional inspection levels. - Sound supplier evaluation system:

The supplier's product quality is scored according to the delivery date and quality… etc. evaluation criteria. - Patrol inspection operations:

Relevant personnel can conduct various stage sampling records for finished products, semi-finished products, finished products, and raw materials in real-time, using patrol inspection operations to directly generate corresponding documents such as quality abnormality orders for quality improvement procedures, processing, and decision-making.