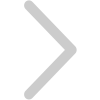

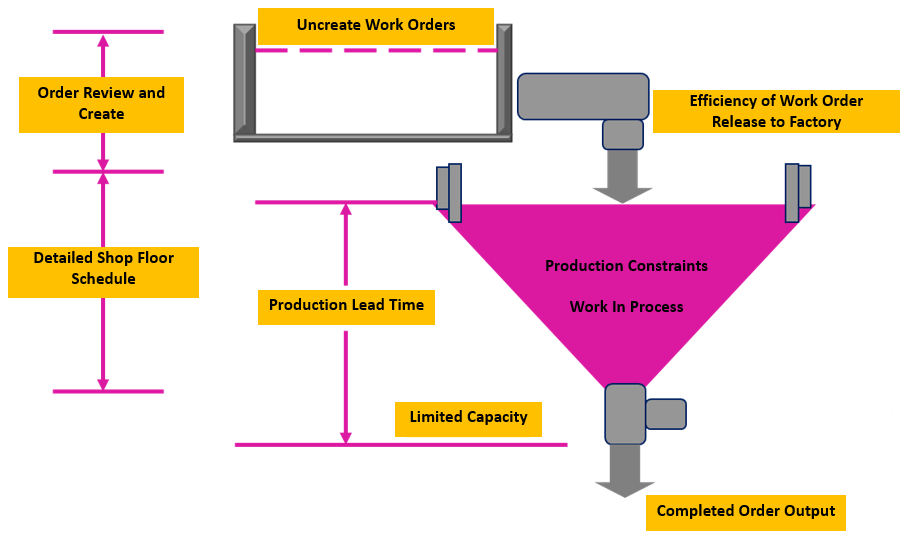

How to coordinate production and sales effectively?

Functions of a Production and Sales Platform

- Standardized operations management

- Accurate demand standards

- Correct production time/quantity

- Small batch/leveled production

- Pull production

- Synchronous engineering

- Multitasking

- Quick changeover or setup change

- Quality improvement

- Visual management/Kanban management

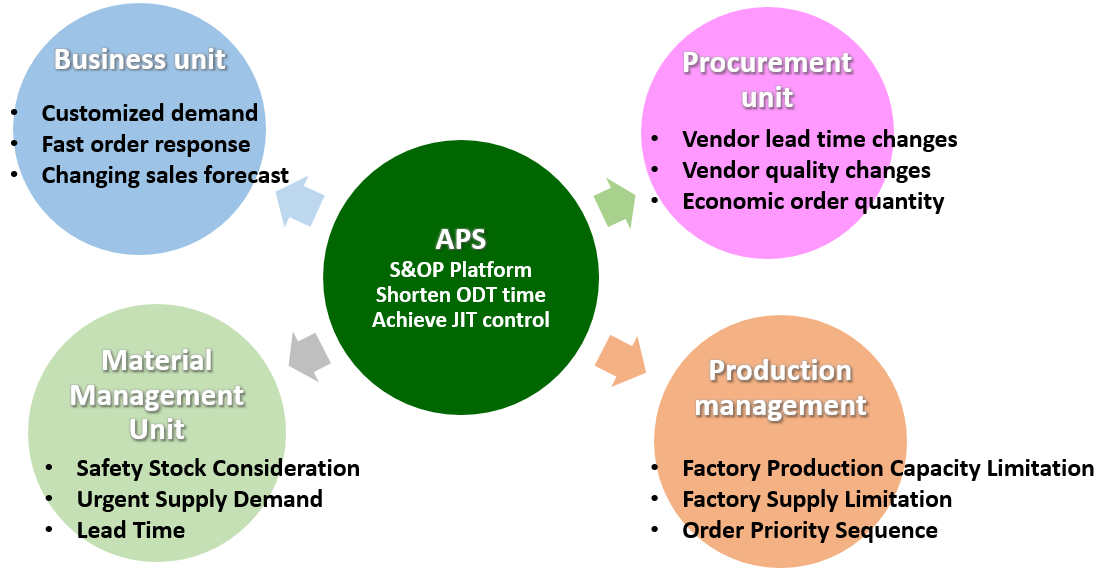

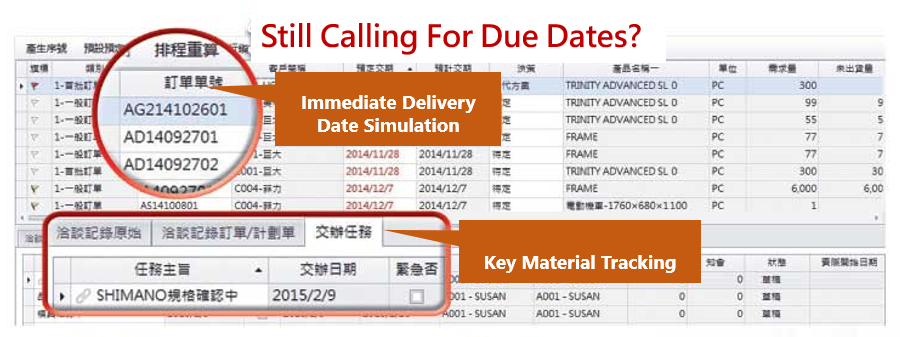

- Reply to new order delivery date:

When the sales team receives an order, we confirm the delivery date. - Order to be placed in rush order mode:

When rush orders occur, prioritize coordination and synchronize scheduling adjustments. - Customers initiated delivery date adjustment change:

The customer requests a delivery date change after it has been incorporated into the production schedule. - Internal abnormality initiates delivery date adjustment change:

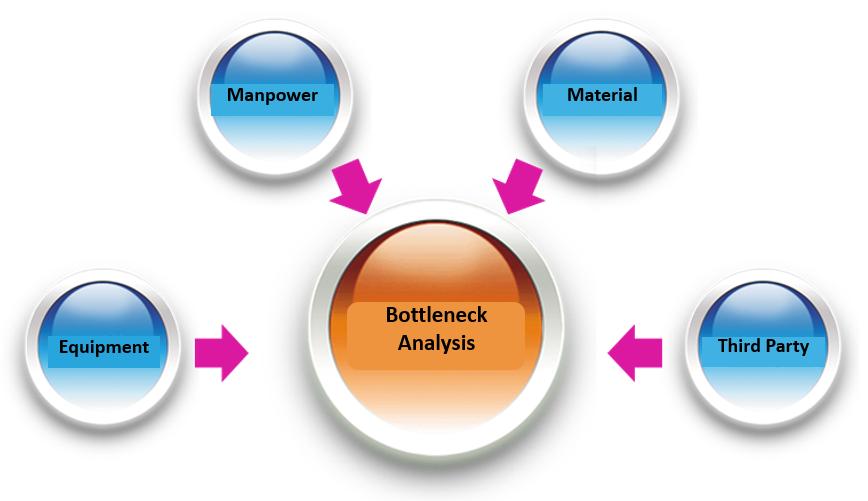

Due to abnormalities such as rescheduling, material shortages, equipment issues, low staffing rates, and low production yield, there is a need to adjust delivery dates. - Production and sales progress tracking platform:

Regular production and sales coordination can be carried out through this platform for shipment progress tracking or delay control.

Phase One: Long-Term Planning (Estimation/Simulated Orders)

- The existing warehouse's available stock is ready for immediate shipment.

- No available stock exists, but if the customer urgently requires shipment, can we place a rush order?

- No available stock exists, but other customer orders are already scheduled in the third phase. Can we reschedule or allocate resources from these orders?

- We can proceed to the order-to-demand phase based on the company's established standard production lead time.

- Whether there are critical materials or key semi-finished production processes, these factors must all be taken into account when considering the delivery date.

- Increased issues in abnormal management can affect production capacity, and all these factors must be considered when determining the delivery date.

- When the sales team receives an order, they use this platform to confirm the delivery date with production management and record the communication process as follows:

- [Expected Delivery Date]: Sales specify the desired delivery date.

- [Scheduled Delivery Date]: Production management responds with the scheduled delivery date.

- [Decision]: Sales respond whether they agree with the date.

- [Update Expected Delivery Date] and [Generate Change Order]: If agreed upon, update the order delivery date data synchronously.

- [Execution Lock]: After delivery date confirmation, the order is locked.

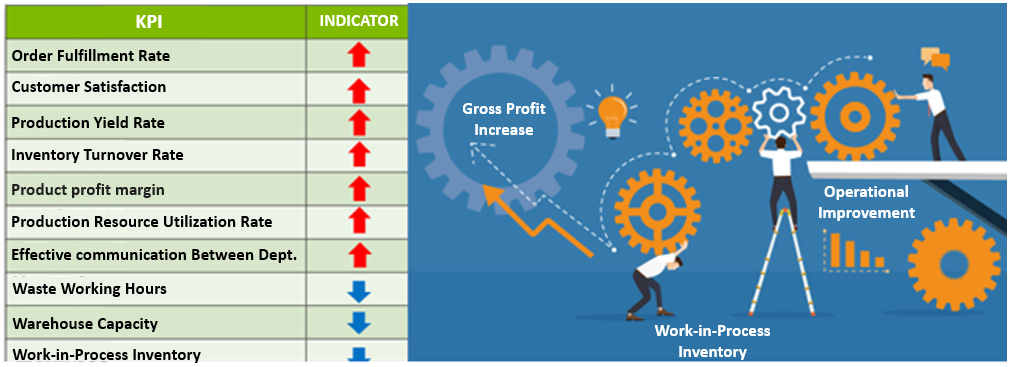

- Improve production and sales relationships.

- Enhance production and sales efficiency.

- Reduce feedback time.

- Eliminate data omissions.

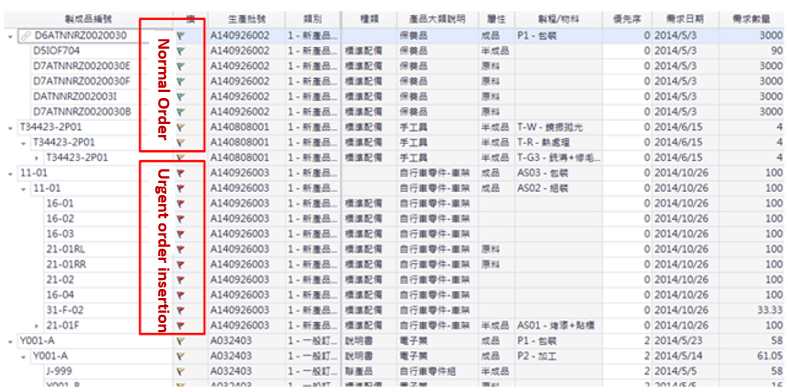

When there is an urgent order, the sales team coordinates with production management through this platform to prioritize and synchronize scheduling adjustments.

|

|

|

|

|

|

|

|

- Quickly coordinate rush orders

- Resolve disorganization issues

- Eliminate chaos from rush order

Phase Two: Mid-Term Planning (Scheduling Expansion)

- During the scheduling expansion, verify the accuracy of BOM (Bill of Materials) and BOP (Bill of Process) information.

- Issue a clear procurement plan.

- Is planned production conducted for shared semi-finished products?

- Utilization of shared materials, substitute materials, and co-produced products.

- When all parameters for a rush order are established, it must be converted into an order on the same day, including issuing the procurement plan, material preparation plan, and production plan.

- Check inventory estimation for critical materials and capacity estimation.

After the production process has commenced, if the customer requests a delivery date change, the sales team coordinates with production management through this platform to make synchronized scheduling adjustments:

- [Expected Delivery Date] Customer requests a change in delivery date.

- [Scheduled Delivery Date] Production management responds with the scheduled delivery date.

- [Decision] Sales respond whether they agree.

- [Update Expected Delivery Date] and [Generate Change Order] should be synchronized to update the order delivery date data after the agreement.

- [Rescheduling] Already scheduled work orders, purchase requisitions, and purchase orders should be rescheduled synchronously.

- [Execution Lock] Order is locked after confirmation.

- Rapid response to order changes.

- Production scheduling can respond in real time.

- Production and sales data are synchronized in real-time.

Due to abnormalities such as rescheduling and material shortages, delivery dates need to be changed. Production management uses this platform to reschedule and provide feedback to sales on delays and revised delivery dates.

- [Scheduled Delivery Date] Production management schedules a new delivery date in advance.

- [Decision] Sales respond whether they agree.

- [Update Expected Delivery Date] and [Generate Change Order] should be synchronized to update the order delivery date data after the agreement.

- [Expected Delivery Date] Sales order delivery date synchronized with production management.

- [Execution Lock] Order is locked after confirmation.

- Rapid response to production line conditions.

- Intelligent scheduling adjustments and delivery date estimation/feedback.

- Sales receive information promptly.

Phase Three: Short-Term Planning (Scheduling Lockdown)

- The dispatching phase, also known as the weekly scheduling table, must be locked to specify daily scheduling for input work orders and output quantities.

- Verify that all material requirements generated by the system have been procured, and materials must be at the station or online at least three days before going online.

- Check fixtures, inspect equipment, and review manpower.

- For rush orders, no changes should be made to the current day or the next three days' schedules.

- If allowing rush orders, a portion of the production capacity (20%) must be reserved for accommodating rush orders.

- Inspect critical material inventory.

- Generally, software tends to focus on scheduling algorithms and logic, often without considering the specific scheduling improvement needs of a business.

- i-TEC ERP's scheduling system combines practical management to provide manufacturing improvement solutions for businesses.

- Production management schedules and dispatches tasks based on priority flags, allowing them to allocate work in a specific order.

Production and Sales Progress Tracking Platform.

Production and sales coordination will use this platform to track shipment progress or delay control:

- [Expected Delivery Date Range] + [Work in Progress]: Confirm the expected shipping information and production progress.

- [Not Closed] + [Completed]: Audit what should have been shipped but hasn't.

- [Expected Delivery Date Overdue] + [Work in Progress] + [Completed] + [Not Closed]: Audit delayed shipping information.

- Increase the efficiency of production and sales meetings.

- Improve on-time delivery rates.

- Standardize production and sales meetings.

Roles for locking/flagging and permissions.

- Prevent data from being modified.

- Special privileges are required to unlock.

- Timestamp records for both locking and unlocking operations.

In production scheduling, in addition to prioritizing based on order delivery dates, flag parameters are used.

[Red Flag]: Rush Order Principle

- Allows for the adjustment of scheduled delivery dates to be before the expected delivery date (indicating rush orders).

- Allows scheduled delivery dates within the production lead time (indicating rush orders).

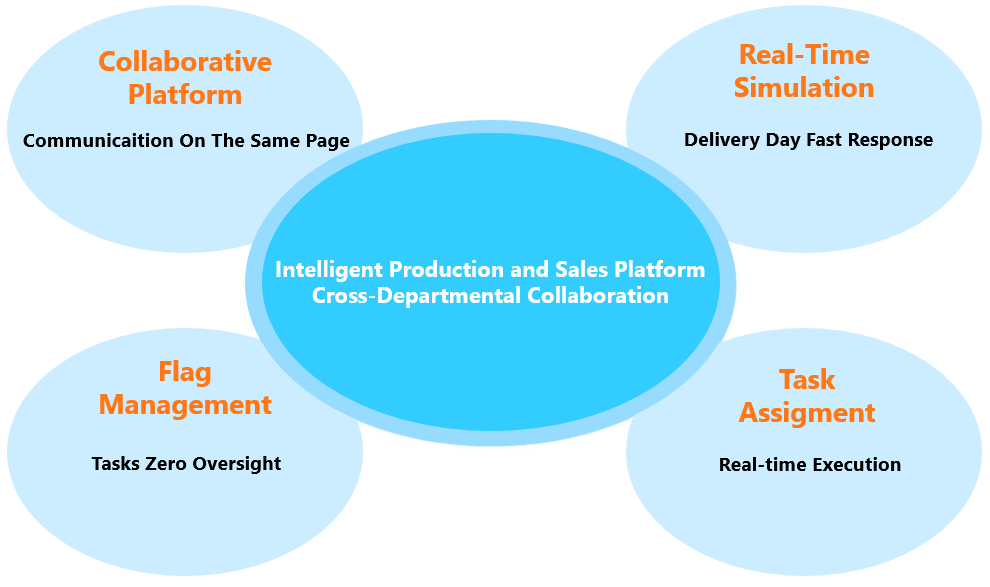

Intelligent Production and Sales Platform

Previous Article

Previous Article